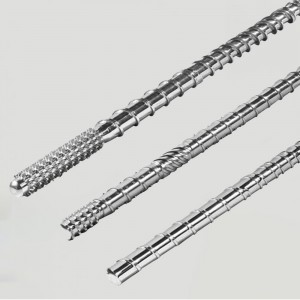

Single Screw Plastic Extruder

Tare da haɓaka wayar da kan muhalli, sake amfani da filastik ya zama batu mai zafi a yau.Mai fitar da dunƙule guda ɗaya yana taka muhimmiyar rawa a tsarin sake amfani da robobi.Ta hanyar sake yin amfani da sharar filastik, bayan narkewa da extrusion, ana iya sake yin ta ta zama samfuran filastik.Wannan ba kawai ceton albarkatun kasa ba ne, har ma yana rage gurɓatar muhalli.

Ka'idar aiki na guda dunƙule extruder ne kamar haka:

1. Ciyarwa: Ana ƙara ƙwayoyin filastik ko foda zuwa sashin abinci na screw extruder ta hanyar tashar abinci.

2. Ciyarwa da narkewa: Screw yana jujjuyawa a cikin ganga don tura barbashi na filastik gaba, sannan a shafa zafi mai zafi da matsa lamba a lokaci guda.Yayin da robobin ke zafi da gogayya a cikin dunƙule da ganga, robobin ya fara narkewa kuma ya zama narke iri ɗaya.

3. Ƙarfafa matsin lamba da yanki mai narkewa: zaren dunƙule a hankali ya zama marar zurfi, yana sa hanyar zirga-zirga ta zama kunkuntar, ta haka yana ƙara matsa lamba na filastik a cikin ganga, da kuma ƙara dumama, narkewa da haɗuwa da filastik.

4. Extrusion: A cikin ganga da ke bayan yankin narke, dunƙule ta fara canza siffar, tana tura narkakkar robobin zuwa mashin ganga, sannan ta ƙara matsawa robobin ta ramin ƙuran ganga.

5. Sanyaya da siffa: Fitar da robobin na shiga cikin ruwan sanyaya ta cikin rami mai sanyi don saurin sanyaya, ta yadda zai taurare da siffa.Yawanci, ramukan mutu da tsarin sanyaya na extruder an tsara su bisa ga siffar samfurin da ake so.

6. Yankewa da tattarawa: Ana ci gaba da fitar da gyare-gyaren extruded daga ramin ƙira, sannan a yanke zuwa tsayin da ake buƙata, kuma ana tattarawa da tattarawa ta hanyar bel mai ɗaukar hoto ko wasu na'urorin tarawa.

1. Aikace-aikacen fasaha na atomatik

Tare da ci gaba da haɓaka fasahar sarrafa kansa, ana sabunta masu fitar da dunƙule guda ɗaya.Tsarin sarrafawa ta atomatik zai iya gane ainihin sa ido da daidaitawa na yanayin gudana na extruder, inganta ingantaccen samarwa da kwanciyar hankali.Haɗe-haɗen ƙira da ƙirar aiki mai hankali kuma suna sauƙaƙe aikin fahimta.

2. Bukatar kare muhallin kore

A cikin duniya, buƙatar kare muhallin kore yana ƙara zama cikin gaggawa.Masu fitar da dunƙule guda ɗaya kuma za su haɓaka a cikin mafi kyawun al'amuran muhalli.Alal misali, haɓaka ƙarin albarkatun robar da ke da alaƙa da muhalli da kayan da za a iya lalata su, da kuma binciken sabbin fasahohin ceton makamashi da rage amfani su ne alkiblar ci gaban gaba.