Twin roba dunƙule ganga siffar dace da ingancin zamani extrusion Lines. Shugabannin kasuwa suna nuna rawar da take takawa wajen dorewa da sabbin abubuwa.

- Masana'antun suna ganin buƙatu yana ƙaruwa yayin da hanyoyin sadarwar firikwensin firikwensin da masu sarrafa AI ke haɓaka amfani da makamashi da rage raguwar lokaci.

- Twin Parallel Screw Barrel Manufacturersbayar da rahoton karɓuwa mai ƙarfi saboda ingantaccen karko da gyare-gyare.

- Guda Guda DayakumaKamfanonin Rumbun Ruwa Guda Dayahar yanzu suna taka rawa, amma ƙirar tagwaye a yanzumamaye fiye da rabin kasuwar Amurka.

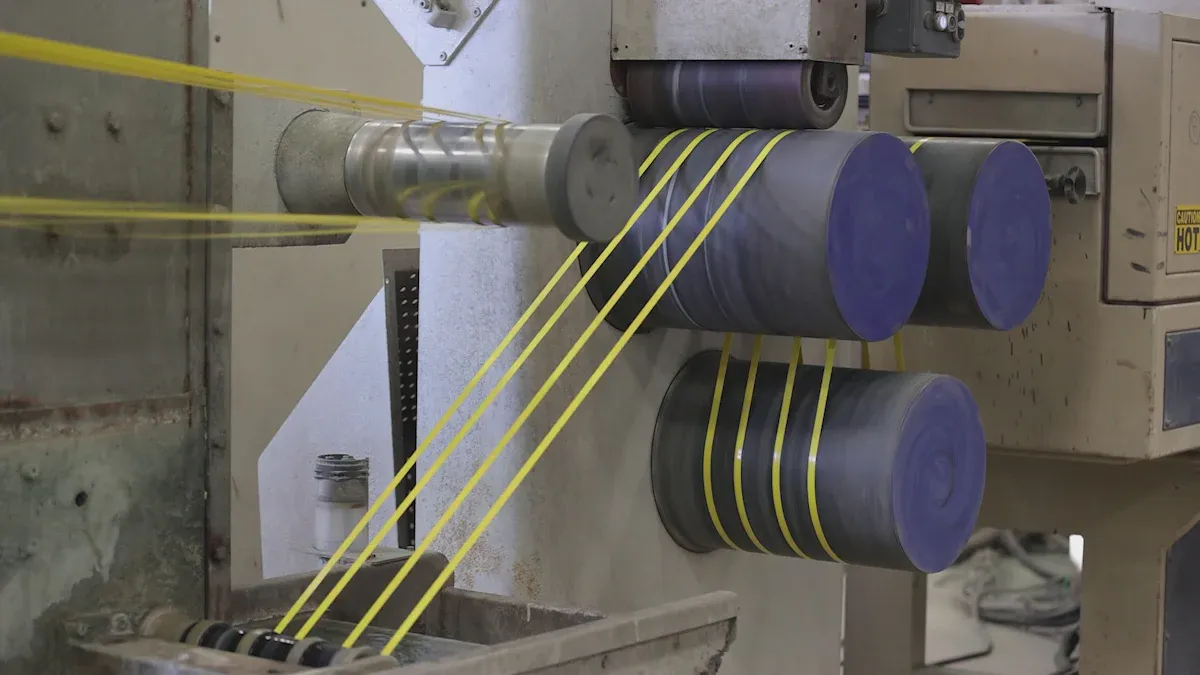

Babban Ayyuka na Twin Plastic Screw Barrel

Isar da Kayayyaki da Haɗuwa

Tagwayen robobi na dunƙule ganga suna taka muhimmiyar rawa wajen motsi da haɗa albarkatun ƙasa a cikin mai fitar da su. Injiniyoyi suna tsara jiragen sama masu dunƙulewa don kamawa da tura granules na filastik gaba. Wannan aikin yana tabbatar da cewa kayan yana motsawa da kyau daga yankin ciyarwa zuwa yankin matsawa. Masu bincike sun yi nazarin yadda waɗannan ganga ke aiki kuma sun sami mahimman abubuwa da yawa:

- Potente da Melish sun raba yankin isarwa zuwa wuraren ciyarwa da matsawa. Sun yi amfani da ƙarfi da ma'aunin ƙarfi don ƙididdige mafi girman abin da zai yiwu, canjin matsa lamba, da ikon da ake buƙata don fitar da sukurori. Ayyukansu ya nuna cewa ganga tagwayen filastik suna ba da ƙarfi da tsayayyen kayan aiki.

- Wilczyński da White sun lura cewa yawancin granules na filastik suna tafiya a cikin ƙananan ɓangaren ganga, kusa da jiragen sama. Ganga da dunƙule suna zafi da granules yayin da suke motsawa, wanda ke taimaka musu narke daidai gwargwado.

- Sauran masana, irin su White da Bawiskar, sun ƙirƙiri nau'ikan da ke bayyana yadda tagwayen robobi na dunƙulewar ganga ke yin narke da kuma haɗa sassa masu ƙarfi da ruwa. Waɗannan samfuran suna taimaka wa masana'antu fahimta da haɓaka haɗawa da narkewa.

Twin roba dunƙule ganga yana tabbatar da cewa kowane bangare na kayan samun gauraye da kuma zafi. Wannan tsari yana haifar da ingantaccen ingancin samfur da ƙarancin lahani.

Narkewa, Daidaitawa, da Kula da Matsi

Narkewa da haɗa robobin daidai gwargwado wani babban aiki ne na ganga tagwayen robobin roba. Dole ne kuma ganga ta sarrafa matsa lamba don kiyaye tsari ya tsaya. Injiniyoyin suna amfani da fasalolin ƙira da yawa don cimma waɗannan manufofin. Teburin da ke gaba yana nuna yadda nau'ikan sigogi daban-daban da yanayin tsari ke shafar narkewa, haɗawa, da matsa lamba:

| Screw Parameter | Tasiri / Bayanin Lambobi |

|---|---|

| Rabon L/D | Matsakaicin L/D mafi girma yana haɓaka haɗakar polymer da filastik ta hanyar tsawaita lokacin zama da rarraba zafi |

| Rabon Matsi | Matsakaicin matsawa mafi girma yana haɓaka filastik da ƙima; mafi kyawun ƙima sun dogara da nau'in kayan aiki |

| Matsakaicin Matsakaici don Filastik na gama-gari | PE: 3-4, PP: 2.5-4, PS: 2-4, PVC mai ƙarfi (Granules): 2-3, PVC mai ƙarfi (foda): 3-4, PVC mai sassauƙa (Granules): 3.2-3.5, PVC mai sassauƙa (foda): 3-5, ABS: 5.-3: 2 PC 2.8-4, PPE: 2-3.5, PA66: 3.7, PA1010: 3, Ƙarfafa Polyester: 3.5-3.7 |

| Siga / Al'amari | Sakamakon Lambobi / Bayani |

|---|---|

| Matsi a cikin ɗakin C-dimbin yawa | Kimanin 2.2 MPa |

| Faɗuwar matsi a yankin tsaka-tsaki | 0.3 MPa |

| Matsi na juyi juzu'i | 0.5 MPa |

| Zazzabi yana ƙaruwa saboda matsa lamba | 40 bar matsa lamba yana haifar da ~ 20 ° C yanayin zafi |

| Mafi kyawun ƙimar ciyarwa da saurin dunƙulewa | 3.6 kg/h ciyarwar abinci a 95 rpm yana haɓaka zafin jiki kuma yana rage raguwar fiber |

| Tushen samar da zafi | Kimanin kashi 80% na narkewar zafin da ake samu ta hanyar juzu'i |

| Sakamakon saurin dunƙulewa akan iri | Nau'in da aka tara yana ƙaruwa a layi tare da saurin dunƙulewa |

| Tasirin adadin abinci akan iri | Nauyin da aka tara yana raguwa tare da ƙimar abinci |

Wadannan sakamakon sun nuna cewa tagwayen robobin roba na dunƙulewa na iya sarrafa yawan zafi da matsi da kayan ke karɓa. Saitunan da suka dace suna taimakawa filastik narke cikakke kuma ya haɗu da kyau. Wannan iko yana haifar da ƙarfi, samfuran iri ɗaya.

Tsaftace Kai da Tsayawa Tsari

Ganga mai dunƙule robobi na tagwaye kuma yana taimaka wa mai fitar da tsafta da kwanciyar hankali. Zane na screws da ganga yana ba da damar tsaftacewa. Yayin da screws ke juyawa, suna shafa juna da bangon ganga. Wannan aikin yana cire ragowar kayan kuma yana hana haɓakawa. Tsaftace ganga yana rage raguwar lokaci kuma a ci gaba da tafiyar da aiki yadda ya kamata.

Zaman lafiyar tsari shine wani fa'ida. Twin roba dunƙule ganga rike ko da matsa lamba da kuma zafin jiki a ko'ina cikin extrusion tsari. Wannan kwanciyar hankali yana nufin cewa injin na iya yin aiki na dogon lokaci ba tare da matsala ba. Masana'antu na iya samar da ƙarin samfura tare da ƙarancin tsayawa da ƙarancin sharar gida.

Tukwici: Kulawa na yau da kullun da saka idanu na tagwayen filastik dunƙule ganga na iya ƙara haɓaka kwanciyar hankali da haɓaka rayuwar kayan aiki.

Ci gaba da Tasirin Duniya na Gaskiya na Twin Plastic Screw Barrel a cikin 2025

Sabbin Kayayyaki da Rubutun don Dorewa

Masu masana'anta yanzu suna amfani da kayan haɓakawa da riguna don sanya tagwayen robobin dunƙule ganga su daɗe kuma suyi aiki mafi kyau. Bakin karfe, CPM10V, yumbura, da rigunan carbide tungsten suna taimakawa ganga ta jure lalacewa da lalata. Wadannan kayan suna kiyaye ganga mai karfi ko da lokacin da ta fuskanci yanayin zafi da matsa lamba yayin extrusion filastik. Gwaje-gwajen aiki sun nuna cewa waɗannan suturar suna inganta haɓakar haɓakawa kuma suna kiyaye tsari. Misali, jiyya na nitriding na iya kaiwa matakan taurin HRC50-65, wanda ke taimakawa ganga ta yi tsayayya da abrasion. Bayanai na gaskiya daga masana'antu sun nuna cewa waɗannan haɓakawa suna rage raguwar lokaci kuma suna hana ɗigogi. Ƙungiyoyin kula da kuma sun ba da rahoton cewa waɗannan ganga suna buƙatar gyare-gyare kaɗan kuma suna dadewa, wanda ke adana kuɗi da kuma ci gaba da samar da kayayyaki ba tare da matsala ba.

Gwajin gwaje-gwaje, kamar waɗanda ke amfani da Coperion ZSK 18 MEGAlab, suna taimaka wa injiniyoyi su gwada sabbin kayayyaki da sutura. Waɗannan gwaje-gwajen suna auna yadda ganga ke sarrafa robobi daban-daban da ƙari. Sakamakon ya nuna cewa sabbin kayan kwalliya suna haɓaka kwanciyar hankali na thermal da juriya. Kamfanoni suna ganin ƙarancin raguwa da ingancin samfur saboda waɗannan haɓakawa.

Daidaitaccen Injiniya da Zane-zanen Ganga na Modular

Daidaitaccen injiniya yana siffata kowane bangare na tagwayen robobin dunƙule ganga. Masana'antu suna amfani da injunan CNC da ingantattun bincike don tabbatar da kowace ganga ta cika ma'auni. Injiniyoyin suna auna madaidaiciyar dunƙulewa zuwa 0.015 mm da ƙaurin saman zuwa Ra 0.4. Waɗannan matsananciyar haƙuri suna taimakawa ganga gauraya da narkar da filastik daidai gwargwado.

Zane-zanen ganga na zamani yana ba da damar sauye-sauye da gyare-gyare da sauri. Ma'aikata na iya maye gurbin sassan da suka sawa ba tare da raba na'urar gaba daya ba. Wannan zane yana ragewadowntime har zuwa 20% kuma yana rage farashin gyara har zuwa 30%. Teburin da ke ƙasa yana nuna wasu mahimman ci gaba:

| Siga | Ƙimar Lambobi / Rage |

|---|---|

| Rage raguwar lokaci saboda modularity | Har zuwa 20% |

| Gyara rage tsadar kuɗi saboda daidaitawa | Har zuwa 30% |

| Nitrided surface taurin (HV) | 920-1000 |

| Alloy hardness (HRC) | 50-65 |

| Dunƙule madaidaiciya | 0.015 mm |

| Tashin saman (Ra) | 0.4 |

Waɗannan ci gaban na taimaka wa masana'antu su riƙe tagwayen robobin su na dunƙule ganga a sama, wanda ke haifar da kyakkyawan aiki da ƙarancin sharar gida.

Haɗin kai tare da Masana'antar Smart da Automation

Masana'antu masu wayo da aiki da kai sun canza yadda masana'antu ke amfani da tagwayen robobin dunƙule ganga. Na'urori masu sarrafa kansa yanzu suna sarrafa zafin jiki, matsa lamba, da sauri tare da babban daidaito. Tsare-tsaren Kisa na Kera (MES) yana taimakawa bin kowane mataki na tsari. Waɗannan tsarin suna haɓakasaurin samarwa da 40-50% kuma yanke lokacin raguwa har zuwa 30%. Kulawa na yau da kullun, da na'urori masu auna firikwensin da bayanai ke jagoranta, yana sa injunan aiki ya daɗe.

Teburin da ke ƙasa yana nuna wasu tasirin da ake iya aunawa:

| Bangaren Ingantawa | Tasiri Mai Aunawa |

|---|---|

| Saurin samarwa | An haɓaka da 40-50% |

| Rage Lokaci | An rage shi har zuwa 30% |

| Inganta Haɓakawa (MES) | Har zuwa 25% riba |

| Inganta Gudun Material | Uniform RTD, ƙarancin lahani da ƙarancin sharar gida |

| Amfanin Makamashi | Kasa fiye da hanyoyin gargajiya |

| Farashin Aiki | An rage ta hanyar amfani da albarkatu mafi kyau |

| Ingancin samfur | Ci gaba da ingantawa |

Kamfanonin da ke amfani da tsarin ingantaccen tsarin ISO9001 tare da ci-gaban dunƙule ganga suna ganin ayyuka masu santsi da ingancin samfur. Abokan ciniki suna samun ingantattun kayayyaki, kuma kamfanoni suna yin gasa a kasuwa.

Inganci, Ingantattun Samfura, da Fa'idodin Dorewa

Twin roba dunƙule ganga yana kawo fayyace riba cikin inganci, inganci, da dorewa. Haɓaka zuwa injina da adana tuƙi10-20% a cikin makamashi. Ƙarfin zafi yana raguwa da 10%, kuma lokutan sake zagayowar sun faɗi daga 30 zuwa 15 seconds tare da mafi kyawun sanyaya. Tsarin dawo da zafi na sharar gida yana kama har zuwa 15% na makamashin da aka rasa, yana rage farashin har ma da ƙari.

Teburin da ke ƙasa yana taƙaita waɗannan fa'idodi:

| Haɓaka Haɓaka da Dorewa | Ƙididdiga mai Tallafawa ko Bayani |

|---|---|

| Ajiye Makamashi | 10-20% raguwa |

| Ingantaccen dumama | 10% ƙarancin kuzari, lokacin zagayowar ya ragu |

| Farfadowar Zafin Sharar gida | Har zuwa 15% na asarar makamashin da aka dawo dasu |

| Yawan Yin Filastik | An ƙara daga 104 g/s zuwa 120 g/s |

| Lokacin farfadowa | Raba daga 18s zuwa 9s |

| Kulawar Hasashen | Rage lokacin raguwa da 15-30% |

| Kayayyakin da suka dace da muhalli | Ƙananan gogayya da lalacewa |

| Ingantattun Ingantattun Samfura | 90% ƙarancin lahani, mafi kyawun fitarwa |

| Rage sharar gida | Ƙananan albarkatun kasa sharar gida |

Waɗannan haɓakawa suna taimaka wa masana'antu yin ƙarin samfuran tare da ƙarancin kuzari da sharar gida. Tagwayen robobi na dunƙule ganga yana tallafawa masana'anta mai dorewa ta hanyar rage lahani da amfani da albarkatu cikin hikima.

Lura: Kamfanoni kamar Zhejiang Jinteng Machinery Manufacturing Co., Ltd. suna amfani da suci-gaba injiniyada ingantattun tsare-tsare don isar da ingantattun tagwayen robobi na dunƙule ganga. Kayayyakinsu na taimakawa masana'antu biyan bukatun sarrafa robobi na zamani a shekarar 2025.

Twin Plastic Screw Barrel yana tsaye a tsakiyar fasahar extrusion na zamani. Masu kera suna samun ingantaccen inganci, tsawon rayuwar sabis, da daidaiton ingancin samfur.

- Gina mai ɗorewayana rage farashin canji

- Daidaitaccen injiniya yana inganta amfani da makamashi

- Zane-zane masu sassauƙa suna tallafawa aikace-aikace iri-iri

Waɗannan fasalulluka suna haifar da nasara na dogon lokaci a cikin haɓakar kasuwannin duniya.

FAQ

Me ke sa tagwayen robobi na dunƙule ganga mai mahimmanci ga masu fitar da kayan zamani?

Twin roba dunƙule ganga samar da daidai hadawa, narkewa, da matsi iko. Waɗannan fasalulluka suna tabbatar da ingancin samfuran inganci da ingantaccen aiki a cikin layukan extrusion na ci gaba.

Tukwici: Daidaitaccen aiki ya dogara da ingantaccen dunƙule da ƙirar ganga.

Sau nawa ya kamata masana'antu su kula da tagwayen robobi na dunƙule ganga?

Ya kamata masana'antu su duba tare da tsaftace ganga akai-akai. Yawancin ƙwararru suna ba da shawarar dubawa kowane wata don hana lalacewa, haɓakawa, da raguwar lokacin da ba zato ba tsammani.

- Kulawa na yau da kullun yana haɓaka rayuwar kayan aiki.

- Gano batutuwan da wuri yana rage farashin gyarawa.

Ta yaya masana'antun ke zaɓar ganga mai dunƙule filastik tagwaye daidai?

Masu kera suna zaɓar ganga bisa nau'in kayan aiki, buƙatun fitarwa, da ƙayyadaddun inji. Yin shawarwari tare da ƙwararrun masu kaya yana tabbatar da kyakkyawan aiki da dorewa.

| Abun Zaɓa | Matsayin Muhimmanci |

|---|---|

| Nau'in Abu | Babban |

| Bukatar fitarwa | Babban |

| Samfurin Inji | Matsakaici |

Lokacin aikawa: Jul-03-2025