Lokacin da nake aiki tare da ƙwanƙwasa ƙwanƙwasa filastik, na ga yadda ƙirar sa ke siffata kowane ɓangaren da muke yi. Nazarin kwaikwaiyo ya nuna cewa ko dakananan canje-canje a dunƙule gudunko yankunan matsawa na iya haɓaka inganci da inganci. Ko ina amfani da aTwin Plastic Screw Barrelko gudu aLayin Samar da Fitar Filastik, hakkiFilastik Machine Screw Barrelya bambanta.

Ayyuka na Filastik Injection gyare-gyaren dunƙule ganga

Lokacin da na kalli zuciyar kowace injin gyare-gyaren allura, na ga ganga mai ɗaukar nauyi yana ɗaukar nauyi. Ba bututu ba ne kawai mai dunƙule dunƙule a ciki. Zane da aiki na dunƙule ganga siffar kowane mataki na gyare-gyaren tsari. Bari in warware manyan ayyukansa da kuma dalilin da yasa kowannensu yana da mahimmanci.

Narkewa da Cakuda na polymers

Abu na farko da ke faruwa a cikin dunƙule ganga shi ne narkewa da cakuɗar pellet ɗin filastik. Ina zuba pellets a cikin hopper, kuma dunƙule ya fara juyawa a cikin ganga mai zafi. Ganga tana da wurare daban-daban na zafin jiki, don haka filastik yana yin zafi a hankali. Yawancin narkewa a zahiri yana fitowa ne daga juzu'i da matsi da ke haifar da dunƙulewa a kan pellets da bangon ganga. Wannan tsari yana kiyaye filastik daga zafi kuma yana taimakawa wajen narkewa daidai.

- Gangaren dunƙulewa yana ƙunshe da dunƙule mai jujjuyawa mai juyawa a cikin ganga tsaye.

- Tumatir na ganga suna dumama ganga kafin in fara, don haka polymer ya tsaya ya fara narkewa.

- Da zarar dunƙule ya juya, yawancin kuzari don narkewa yana fitowa ne daga juzu'i tsakanin dunƙule da bangon ganga.

- Zane na dunƙule, musamman yadda zurfin tashar ke samun ƙarami a cikin sashin matsawa, yana tilasta robobin da ba a narkewa ba a bangon ganga mai zafi. Wannan yana haɓaka narkewa da haɗuwa.

- Yayin da filastik ke motsawa gaba, tafkin narke yana girma har sai komai ya narke. Ci gaba da sassaske narkakken robobin yana ƙara haɗawa.

A koyaushe ina kula da yadda filastik ke narkewa da haɗuwa. Idan narke ba iri ɗaya ba ne, Ina ganin matsaloli kamar ɗigon ruwa ko raunin rauni a sassan ƙarshe. Tsarin dunƙule ganga, gami da nasatsayi, farar, da zurfin tashar, yana haifar da babban bambanci a yadda yake narkewa da haɗa nau'ikan robobi daban-daban.

Tukwici:Yawancin ƙarfin tuƙi a cikin ganga mai dunƙule-kimanin 85-90% - yana shiga cikin narkewar filastik, ba kawai motsa shi gaba ba.

Isar da Homogenization

Da zarar robobin ya fara narkewa, ganga mai dunƙule yana ɗaukar wani muhimmin aiki: isar da kayan gaba da tabbatar da cewa sun yi daidai. Ina tsammanin wannan a matsayin yankin "mai kula da inganci" a cikin injin. An raba ganga mai dunƙulewa zuwa manyan sassa uku, kowanne da aikin sa:

| Screw Zone | Mabuɗin Halaye | Ayyukan Farko |

|---|---|---|

| Yankin ciyarwa | Tashar mafi zurfi, zurfin zurfi, 50-60% tsayi | Yana jigilar daskararrun pellets zuwa ganga; fara zafi ta hanyar gogayya da gudanarwa; ƙanƙanta kayan cire aljihun iska |

| Yankin Matsi | A hankali raguwar zurfin tashar, 20-30% tsayi | Narke pellets filastik; matsa lamba abu yana ƙaruwa; yana kawar da iska daga narkewa |

| Yankin Mita | Tashar mafi ƙanƙanta, zurfin zurfi, 20-30% tsayi | homogenizes narke zafin jiki da abun da ke ciki; yana haifar da matsa lamba don extrusion; sarrafa kwarara kudi |

Na lura cewa juzu'i na dunƙule ganga-kamar farar da zurfin da dunƙule jirage-kai tsaye rinjayar yadda robobi motsi da cakude.Gangatattun ganga, alal misali, taimakawa ci gaba da matsa lamba kuma inganta yawan kayan da zan iya sarrafawa, ko da a babban gudu. Idan ina so in haɓaka kayan aiki, zan iya ƙara farar dunƙule ko amfani da buɗewar abinci mafi girma. Duk waɗannan tweaks ɗin ƙira suna taimaka wa ganga mai dunƙulewa ta isar da tsayayyen narke iri ɗaya zuwa ƙirar, wanda ke nufin ƙarancin lahani da ƙarin daidaiton sassa.

- Kula da zafin jiki na gangayana da mahimmanci don narkewa iri ɗaya da ingantaccen tsari.

- Yankunan dumama da yawa tare da haɓaka yanayin zafi a hankali zuwa ga mutuwa suna rage lahani da inganta lokutan zagayowar.

- Tsarin dunƙulewa yana inganta haɗawa da isar da inganci.

Allura da Cika Mold

Bayan robobin ya narke kuma ya haɗe, ganga mai dunƙule yana shirya don babban lokacin: allurar narkakken robobin a cikin ƙirar. Ga yadda nake ganin tsarin yana buɗewa:

- Ganga mai dunƙulewa tana karɓar ɗanyen pellet ɗin filastik daga hopper.

- Screw ɗin yana jujjuya kuma yana motsawa gaba a cikin ganga mai zafi, yana narkewa, yana haɗuwa, yana daidaita filastik.

- Yanke injina ta dunƙule yana haifar da zafi mai zafi, yana rage ɗankowar robobin ta yadda zai iya gudana.

- Narkakkar kayan yana tattarawa a gaban dunƙule, suna yin “harbi” wanda shine daidai adadin da za a cika mold ɗin.

- Dunƙule allurar narkakkar harbi a babban matsi da gudu cikin mold rami.

- Screw yana kula da matsa lamba don tabbatar da cewa ƙirar ta cika gaba ɗaya kuma tana rama kowane raguwa.

- Bayan na'urar ta cika, dunƙule ta koma baya don shirya don sake zagayowar gaba yayin da ɓangaren ke yin sanyi.

A koyaushe ina kallon aikin dunƙule ganga a wannan matakin. Idan zafin narkewa ko ƙimar kwarara ba ta daidaita ba, Ina samun cikar ƙira mara daidaituwa ko lokutan sake zagayowar. Ingantacciyar ganga ta dunƙule a cikin narkewa da motsin filastik da sauri yana taimaka mini in ɗan gajeren lokacin sake zagayowar da babban inganci. Shi ya sa nake mai da hankali sosai ga ƙira da yanayin Ƙararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa ) ya yi - yana sarrafa dukan tsari daga farko zuwa ƙarshe.

Screw Design da Tasirinsa akan Sakamakon Molding

Daidaita Geometry na Screw zuwa Nau'in Guduro

Lokacin da na zaɓi dunƙule don injina, koyaushe ina tunanin irin guduro da nake shirin amfani da shi. Ba kowane dunƙule yana aiki da kyau tare da kowane filastik ba. Yawancin shagunan suna amfani da sukurori na gama-gari, amma na ga yadda waɗannan zasu iya haifar da matsaloli kamar narkewar da ba ta dace ba da baƙar fata a cikin samfurin ƙarshe. Wannan saboda wasu resins suna buƙatar ƙirar dunƙule ta musamman don guje wa matattun tabo da kiyaye kayan narke.

- Shingayen sukurori sun raba tsayayyen pellets daga narkakken robobi, wanda ke taimakawa narke kayan cikin sauri da rage amfani da kuzari.

- Haɗin sassan, kamar Maddock ko masu haɗin zig-zag, tabbatar da narke zafin jiki da launi suna tsayawa ko da, don haka ina ganin ƙarancin alamun kwarara da layin walda.

- Wasu ƙirar dunƙule, kamar CRD dunƙule dunƙule, amfani da elongtional kwarara maimakon karfi. Wannan yana kiyaye polymer daga rushewa kuma yana taimaka mini in guje wa gels da canza launi.

Nazarin masana'antu ya nuna cewa kusan kashi 80% na injuna suna da lamuran lalatawar guduro masu alaƙa da ƙirar dunƙule. A koyaushe ina daidaita ma'aunin juzu'i da nau'in resin don kiyaye sassana da ƙarfi kuma ba su da lahani.

Tasiri kan Narke, Haɗawa, da Ingantaccen Fitarwa

Geometry na dunƙule yana siffanta yadda filastik ke narkewa, gaurayawa, da gudana. Na lura cewa ci-gaba na dunƙule ƙira, kamar shãmaki jirgin sama da cakude sassa, tura unnarke polymer kusa da ganga ganga. Wannan yana haɓaka dumama shear kuma yana taimakawa narke ya zama mafi daidaituwa.

Anan ga saurin kallon yadda daban-daban screw geometries ke yin:

| Nau'in Geometry na Screw | Narke Ƙarfafawa | Hadawa Tasiri | Ingancin fitarwa |

|---|---|---|---|

| Barrier Screw | Babban | Matsakaici | Da kyau, idan kayan aiki ya fi kyau |

| Screw Sashe Uku | Matsakaici | Babban | Yayi kyau sosai tare da haɗakar da ta dace |

| Maddock Mixer | Matsakaici | Babban | Mafi kyawun launi da daidaiton yanayin zafi |

Kullum ina nufin daidaitawa. Idan na tura don samar da kayan aiki mafi girma, Ina haɗarin rasa daidaito. Thedama dunƙule zanea cikin ganga na allurar filastik ɗina yana taimaka mini ci gaba da narke zafin jiki, rage lahani, da isar da daidaitattun sassa kowane zagayowar.

Tukwici: Ina duba ingancin narkewa ta kallon daidaiton launi da ƙarfin sashi. Ƙaƙƙarfan ƙira mai kyau yana sa wannan sauƙi.

Zaɓin kayan abu don Filastik Allurar gyare-gyaren dunƙule ganga

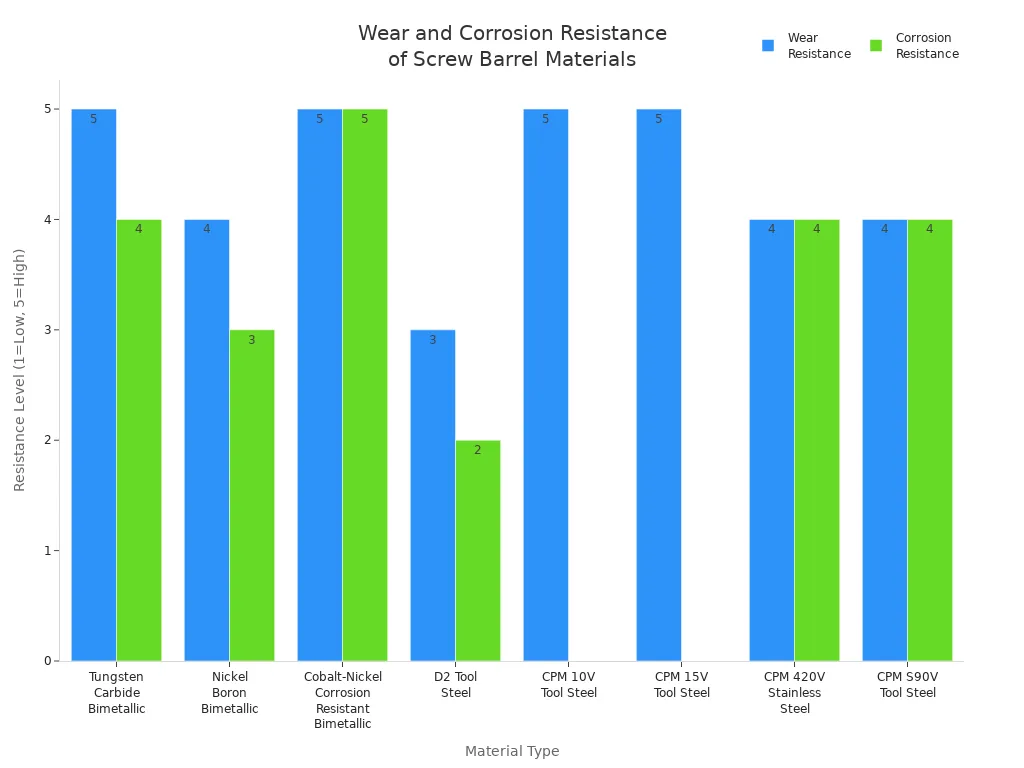

Juriya da lalacewa

Lokacin da na ɗauki kayan don aFilastik Allurar gyare-gyaren dunƙule ganga, Kullum ina tunanin yadda aikin yake da wuyar gaske. Wasu robobi suna da filayen gilashi ko ma'adanai waɗanda ke aiki kamar takarda yashi, suna sanye da dunƙule da ganga cikin sauri. Wasu, kamar PVC ko resins mai ɗaukar harshen wuta, na iya zama mai lalacewa sosai. Ina son kayan aikina su dawwama, don haka ina neman kayan da suka dace da lalacewa da lalata.

Anan ga saurin duba wasu zaɓuɓɓuka gama gari:

| Nau'in Abu | Saka Resistance | Juriya na Lalata | Mafi kyawun Harka Amfani |

|---|---|---|---|

| Nitrided Karfe | Yayi kyau | Talakawa | Ba a cika ba, resins mara lalacewa |

| Ganga Bimetallic | Madalla | Madalla/Mai kyau | Cikakkun abubuwa, masu lalata, ko lalata |

| Kayan aiki Karfe (D2, jerin CPM) | Babban | Matsakaici/Maɗaukaki | Gilashi/ma'adinai cike ko tauri ƙari |

| Ganga Masu Rufe Na Musamman | Mai Girma | Babban | Matsananciyar lalacewa/lalata, resins mai ƙarfi |

Na ga cewa yin amfani da ganga bimetallic ko karafa na kayan aiki na iya tsawaita rayuwar kayana. Wadannan kayan suna tsayayya da fashewa da harin sinadarai. Lokacin da na yi amfani da haɗin da ya dace, Ina kashe lokaci kaɗan don gyarawa da ƙarin lokacin yin sassa masu kyau.

Tukwici: Idan na aiwatar da robobin da ke cike da gilashi ko kuma masu hana harshen wuta, koyaushe ina zabar ganga mai ci gaba da sutura ko bimetallic liners. Wannan yana kiyaye jadawalin kulawa na da tsinkaya da ƙarancin lokacin raguwa na.

Zaɓin Kaya don Takamaiman Polymers da Additives

Kowane filastik yana da halayensa. Wasu suna da laushi, yayin da wasu suna da rashin ƙarfi akan kayan aiki. Lokacin da na zaɓi kayan don dunƙulewa da ganga na, na daidaita su da robobi da abubuwan da nake amfani da su.

- Gilashin fibers da ma'adanai suna tauna karafa masu laushi, don haka zan je neman allurai masu tauri ko kayan kwalliyar carbide tungsten.

- Rarraba robobi, kamar PVC ko fluoropolymers, suna buƙatar ganga da aka yi daga gami da tushen nickel ko bakin karfe.

- High-zazzabi resins iya haifar da thermal gajiya, don haka na duba cewadunƙule da gangafadada daidai gwargwado.

- Idan na yi amfani da kayan daban-daban da yawa, wasu lokuta nakan ɗauki zanen dunƙule na yau da kullun. Ta wannan hanyar, zan iya musanya ɓangarorin da suka lalace ba tare da maye gurbin duka dunƙule ba.

A koyaushe ina magana da mai ba da guduro dina don shawara. Sun san waɗanne kayan aiki mafi kyau da robobin su. Ta hanyar zabar kayan da suka dace, Ina kiyaye ganga mai gyare-gyaren Filastik ɗina yana gudana cikin kwanciyar hankali da guje wa rugujewar mamaki.

Sabuntawa a Fasahar Injection Plastics Molding Screw Ganga Fasaha

Nagartaccen Rufi da Maganin Sama

Na ga yadda ci-gaba mai rufi da jiyya na saman za su iya yin babban bambanci a tsawon lokacin da ganga na dunƙule ya ƙare. Lokacin da na yi amfani da ganga tare da rufin bimetallic ko tungsten carbide coatings, na lura da ƙarancin lalacewa da raguwa. Waɗannan suturar suna taimaka wa ganga don tsayayya da lalata da lalata, ko da lokacin da nake gudanar da abubuwa masu tauri kamar resins masu cika gilashi. Wasu sutura suna amfani da nano-materials, waɗanda ke taimakawa tare da zubar da zafi da kuma kiyaye tsarin aiki. Ina kuma son cewa waɗannan magungunan suna rage hulɗar ƙarfe da ƙarfe, don haka dunƙule da ganga ba sa niƙa juna da sauri.

Ga abin da nake nema a cikin kayan kwalliyar zamani:

- Alloys masu jurewa sawa waɗanda suka dace da kayan da nake sarrafawa

- Jiyya na saman da ke kula da yanayin zafi mai zafi da m sunadarai

- Rubutun da ke kiyaye tsarin aiki kuma ya rage lokacin raguwa

Lokacin da na ɗauki suturar da ta dace, Ina kashe lokaci kaɗan akan kulawa da ƙarin lokacin yin sassa masu kyau. Ƙwarewar ƙarfe yana da mahimmanci a nan. Daidaitaccen haɗin gwal da sutura na iya ninka ko ma sau uku rayuwar sabis na kayan aikina.

Zane-zane na Musamman don Aikace-aikace na Musamman

Wani lokaci, Ina bukatan fiye da daidaitaccen ganga kawai. Tsare-tsare na al'ada suna taimaka mini warware ƙalubalen gyare-gyare na musamman. Misali, Na yi amfani da ganga tagwayen dunƙulewa don inganta haɗawa da sarrafa zafi. Na kuma ga screws na al'ada waɗanda aka tsara don haɓaka lokutan zagayowar, haɓaka ingancin narkewa, da rage yawan sausaya.

Wasu zaɓuɓɓukan da na yi la'akari da su don ƙirar al'ada:

- Screws da ganga da aka yi daga ƙarfe na musamman kamar D2 Tool Steel ko maki CPM

- Tauraruwar saman kamar Stelite ko Colmonoy don ƙarin dorewa

- Rubutun ganga da aka keɓance don takamaiman kayan aiki, kamar tushen nickel tare da carbide don polymers masu cika gilashi

- Majalisun bawul na al'ada da iyakoki na ƙare tare da ci-gaba mai sutura

Magani na al'ada ya bar ni in daidaita kayana zuwa ainihin bukatun tsari na. Wannan yana nufin mafi kyawun sashi, saurin hawan keke, da ƙarancin lokaci. A koyaushe ina aiki tare da ƙungiyar ƙira wacce ta fahimci aikace-aikacena kuma tana iya sadar da fasaha mai inganci.

Gano da Shirya Shirya Matsalolin Screw Barrel

Alamomin gama-gari na sawa ko gazawa

Lokacin da na kunna injina, koyaushe ina sa ido don alamun gargaɗin da wuri cewa wani abu ba daidai ba ne da ganga mai dunƙulewa. Gano waɗannan batutuwa da wuri yana taimaka mini in guje wa manyan matsaloli daga baya. Ga wasu abubuwan da nake kallo:

- Abubuwan da ke yawo a kusa da ganga, wanda yawanci yana nufin sawa hatimi ko sharewa da yawa.

- Sassan da ke fitowa tare da masu girma dabam ko baƙar fata-waɗannan sukan yi nuni zuwa ga rashin daidaituwa ko gurɓatawa.

- Yanayin aiki mafi girma, wani lokaci yana haifar da gogayya ko haɓakar carbon a cikin ganga.

- M hayaniya ko girgiza yayin aiki. Wadannan na iya nufin rashin daidaituwa, karyewar bearings, ko ma wani bakon abu a ciki.

- Matsawa spikes ko rashin narke kwarara, wanda ya sa ya yi wuya a cika m yadda ya kamata.

- Toshewa ko haɓaka kayan abu a cikin ganga, yana haifar da raguwar lokaci da ɓarna mara kyau.

- Matsalolin haɗaɗɗiyar launi ko gurɓata, galibi daga abin da ya rage ko rashin kulawar zafin jiki.

- Lalacewar gani ko rami, musamman idan na gudanar da resins masu lalata.

- Jirgin sama da aka yi amfani da shi ko rufin ganga, wanda na fi gani sau da yawa lokacin amfani da filaye masu lalata kamar fiber gilashi.

- Narkewa a hankali, ƙarin tarkace, da tsayin lokutan zagayowarkamar yadda kayan aiki ke lalacewa.

Idan na lura da ɗaya daga cikin waɗannan alamun, na san lokaci ya yi da za a duba ganga mai dunƙulewa kafin abubuwa su yi muni.

Nasihu masu Hakuri da Magance matsala

Don ci gaba da yin aiki da injina, Ina bin tsarin kulawa na yau da kullun. Ga abin da ya fi aiki a gare ni:

- Ina amfani da man shafawa kawai da masana'anta suka ba da shawarar.

- Ina duba matakan mai na hydraulic kowace rana kuma in maye gurbin mai akan jadawalin.

- Ina kallon zafin mai kuma ban taɓa barin ya yi zafi sosai ba.

- Ina duba hoses, famfo, da bawuloli don yatso ko lalacewa.

- Ina tsaftacewa da kuma ƙara ƙarfafa makada a kowane wata.

- Ina amfani da hoton zafi don gano matsalolin dumama da wuri.

- Ina sa ido kan lokutan zagayowar, adadin tarkace, da amfani da makamashi don kama al'amura kafin su girma.

- Ina tsaftace kullun da ganga don hana haɓakawa.

- Ina tabbatar da dunƙule ya tsaya madaidaiciya kuma a daidaita yayin shigarwa.

- Ina horar da ƙungiyara don gano farkon alamun lalacewa da kuma ci gaba da daidaita yanayin aiki.

Tsayawa kan waɗannan ayyuka yana taimaka mini in guje wa ɓarna kuma yana kiyaye layin samarwa na mai inganci.

Lokacin da na mai da hankali kan ilimin kimiyyar da ke bayan ganga mai gyare-gyaren filastik, na ga sakamako na gaske. Ina samun mafi kyawun sassa, saurin hawan keke, da ƙarancin lokacin hutu.

- Ƙananan farashin kulawa

- Ingantattun ingancin samfur

- Rayuwar kayan aiki mai tsayi

Kasancewa mai kaifi tare da kimiyyar dunƙule ganga yana kiyaye masana'anta amintacce da inganci.

FAQ

Wadanne alamomi ne ke gaya mani ganga mai dunƙulewa na buƙatar maye gurbin?

Ina ganin ƙarin baƙaƙen tabo, sassan da ba daidai ba, ko bakon surutai. Idan na ga waɗannan, Ina duba ganga mai dunƙule don lalacewa ko lalacewa nan da nan.

Sau nawa zan wanke ganga mai dunƙulewa?

Ina tsaftace ganga na dunƙule bayan kowane canji na abu. Don gudana na yau da kullun, Ina dubawa da tsaftace shi aƙalla sau ɗaya a mako don hana haɓakawa.

Zan iya amfani da ganga dunƙule guda don kowane nau'in robobi?

- Ina guje wa amfani da ganga mai dunƙulewa don kowane filastik.

- Wasu robobi suna buƙatar kayan musamman ko sutura don hana lalacewa ko lalata.

Lokacin aikawa: Agusta-20-2025