Ganga mai dunƙule guda don sake yin amfani da granulation na taimaka wa injuna su daɗe ta hanyar yaƙi da lalacewa da tsagewa. Yawancin masu aiki suna zaɓar aMai Bayar da Filastik guda ɗayako aPvc Pipe Single Screw Barrel Manufacturersaboda wannan dalili. Ko daFilm Blown Screwmasu amfani suna ganin ayyuka masu santsi da ƙarancin lalacewa tare da ganga madaidaiciya.

Ganga mai dunƙule guda ɗaya don sake amfani da granulation: Rage lalacewa da hawaye

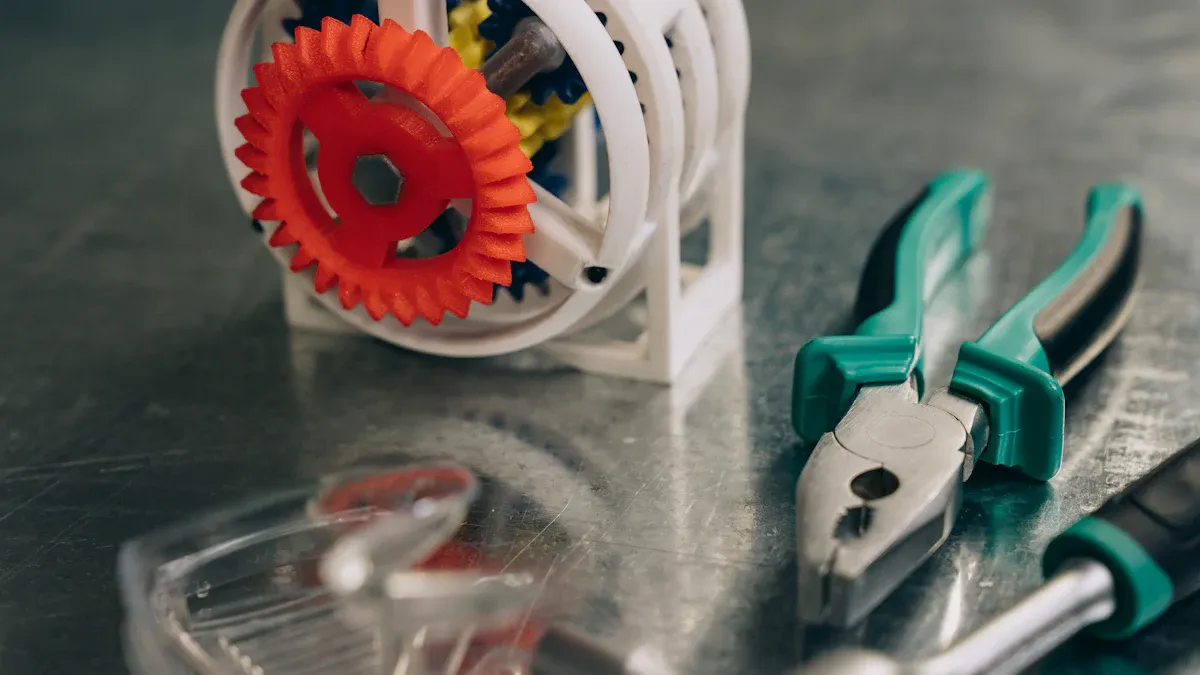

Babban Ayyuka a cikin Filastik Granulation

Filastik granulation yana juya robobin sharar gida zuwa ƙananan pellets iri ɗaya. Wannan tsari yana taimakawa sake amfani da shuke-shuke sake amfani da kayan da kuma rage sharar gida. Ganga mai dunƙule guda ɗaya don sake yin amfani da granulation yana taka muhimmiyar rawa a wannan tsari. Yana motsawa, narke, kuma yana siffata robobin don a iya yanke shi cikin pellets.

Anan ga manyan matakai a cikin granulation na filastik waɗanda ke shafar yadda kayan aikin ke aiki sosai:

- Ma'aikata suna tattara da kuma rarraba robobi don tabbatar da cewa kayan sun yi daidai.

- Injin suna tsaftacewa da yanke robobin don cire datti da yin ƙananan guda.

- Filayen da aka shredded yana bushewa don cire ruwa wanda zai iya cutar da samfurin ƙarshe.

- Ganga mai dunƙule guda ɗaya ta narke kuma tana tura robobin ta cikin mutu don samar da igiyoyi.

- Yankan yankan zaren a cikin ko da granules.

- Granules suna sanyi kuma suna wucewa ta cikin tacewa don cire duk wani datti da ya ragu.

Masu bincike sun gano cewa nau'in filastik, girman granules, da yadda injin ke tafiyar da komai. Kyakkyawan sarrafa tsari yana kiyaye kayan aiki da kyau kuma yana taimakawa yin pellets masu inganci. Masana kimiyya kuma suna amfani da susamfura don nazarin yadda granules ke samuwa da watsewa. Waɗannan karatun suna taimaka wa injiniyoyi su ƙirƙira ingantattun injuna da haɓaka tsarin sake amfani da su.

Manyan Dalilan Dake Ciki da Yagewa a cikin Tsarukan Sake yin amfani da su

Sawa da tsagewana iya rage injin sake yin amfani da su kuma ya haifar da gyare-gyare masu tsada. Abubuwa da yawa suna haifar da wannan lalacewa yayin granulation filastik:

- Wuraren robobi masu ƙarfi ko abubuwa na waje suna iya yayyafa ganga ko yayyafa ganga.

- Babban yanayin zafi da matsa lamba a cikin ganga na iya raunana ƙarfe na tsawon lokaci.

- Wasu robobi suna ɗauke da sinadarai waɗanda ke yin maganin ƙarfe, suna haifar da lalata.

- Matsakaicin saurin dunƙulewa da nauyi mai nauyi yana ƙaruwa, wanda ke haifar da ƙarin ɓarna.

- Rashin tsaftacewa ko abin da ya rage zai iya haɓakawa kuma ya haifar da tabo a cikin ganga.

Dole ne masu aiki su lura da waɗannan matsalolin. Idan sun yi watsi da su, ganga guda ɗaya don sake amfani da granulation bazai daɗe ba. Bincika akai-akai da aiki a hankali suna taimakawa rage waɗannan haɗari.

Siffofin ƙira waɗanda ke Rage Ƙarfafawa da Lalata

Injiniyoyi suna tsara ganga mai dunƙulewa guda don sake amfani da granulation don yaƙar lalacewa da tsagewa. Suna amfani da kayan aiki na musamman da sutura don kare ganga daga lalacewa. Ga wasu mahimman abubuwan ƙira:

- Masu masana'anta suna amfani da ƙarfe mai ƙarfi kamar 38CrMoAl, waɗanda ke tsayayya da abrasion da lalata.

- Ganga tana tafiya ta hanyar nitriding. Wannan yana sa saman ya yi ƙarfi sosai, don haka yana iya ɗaukar robobi masu ƙazanta da matsi mai ƙarfi.

- Wasu ganga suna da gawa na tushen nickel ko ma Layer carbide tungsten. Waɗannan yadudduka suna ƙara ƙarin ƙarfi kuma suna kiyaye ganga daga lalacewa da sauri.

- Ƙaƙƙarfan Layer na chromium plating yana taimakawa wajen dakatar da tsatsa da hare-haren sinadarai.

- Daidaitaccen mashin ɗin yana kiyaye cikin ganga santsi. Wannan yana rage juzu'i kuma yana dakatar da abu daga mannewa ko haifar da karce.

- Injiniyoyin suna tabbatar da walda da haɗin gwiwa suna da santsi da matsi. Wannan yana hana tsagewar inda lalata zata iya farawa.

- Wasu ƙira suna ba da izini don sauƙin sauyawa na sassa masu girma, don haka kulawa yana da sauri da rahusa.

Tukwici: Zaɓin ƙirar ganga mai kyau da kayan aiki don kowane nau'in filastik na iya yin babban bambanci a tsawon lokacin da kayan aiki ke daɗe.

Waɗannan fasalulluka suna taimaka wa ganga dunƙule guda don sake yin amfani da granulation ta kasance mai ƙarfi, koda lokacin aiki da robobi masu tauri ko datti. Tsire-tsire da ke amfani da waɗannan ganga suna ganin ƙarancin lalacewa da ƙarancin gyarawa.

Ayyukan Ayyuka da Kulawa don Tsawon Rayuwar Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙwara

Mafi kyawun Ma'aunin Aiki don Rage Sawa

Masu aiki za su iya taimakawa ganga dunƙule guda don sake yin amfani da granulation na tsawon lokaci ta hanyar sarrafa injuna a saitunan da suka dace. Ya kamata su kiyaye zafin jiki da matsa lamba a cikin kewayon da aka tsara don kowane nau'in filastik. Gudun dunƙule a tsayayyen gudu yana taimakawa hana damuwa kwatsam akan ganga. Lokacin da ma'aikata suka guji yin lodin injin, suna rage juzu'i da zafi, wanda ke nufin rage lalacewa. Hakanan yana taimakawa wajen amfani da filastik mai tsafta, wanda aka jera domin datti da guntuwar ƙarfe na iya toshe cikin ganga.

Tukwici: Koyaushe bincika jagororin masana'anta don mafi kyawun zafin jiki, saurin gudu, da saitunan matsa lamba don kowane nau'in filastik.

Nasihu da Jadawalin Kulawa na yau da kullun

Kulawa na yau da kullun yana kiyaye ganga dunƙule guda don sake yin amfani da granulation a saman siffa. Yawancin karatu sun nuna cewa kiyayewa na yau da kullun yana taimakawa wajen gano matsaloli da wuri kuma yana kiyaye injina ya daɗe. Ga wasu kyawawan ayyuka:

- Duba ganga da dunƙule a kan saita jadawalin.

- Tsaftace da shafawa sassa masu motsi don dakatar da tsatsa da rage gogayya.

- Sauya ɓangarorin da suka lalace kafin su haifar da manyan al'amura.

- Ƙirƙirar kayan aiki don ci gaba da yin aiki da kyau.

- Ajiye cikakken bayanan duk ayyukan kulawa.

Wadannan matakan suna taimaka wa masu aiki su kama kananan matsaloli kafin su juya zuwa manyan gyare-gyare. Tsire-tsire da ke bin atsarin kulawa na yau da kullunganin ƙarancin lokaci, ajiye kuɗi, kuma kiyaye kayan aikin su lafiya.

Zabar Kayan da Ya dace da Sufuri

Zaɓin kayan aiki masu dacewa da sutura suna haifar da babban bambanci a tsawon lokacin da kayan aiki ya kasance. Bincike ya nuna cewa ci-gaba na jiyya kamar nitriding, electroplating, da thermal spraying na iya sa ganga ta yi tauri da juriya ga lalacewa. Wasu nazarin suna nuna fa'idodin yin amfani da suturar multilayer ko abubuwan haɗin gwiwa na musamman don yaƙi da lalata da lalata. Lokacin da masu aiki suka ɗauki ganga da aka yi daga ƙaƙƙarfan gami kuma suna ƙara matakan kariya, suna taimakawa ganga guda ɗaya don sake yin amfani da granulation ta tsaya tsayin daka ga ayyuka masu tsauri kuma suna daɗe.

Ganga mai dunƙule guda ɗaya don sake yin amfani da granulation yana taimaka wa tsire-tsire su rage gyare-gyare da raguwar lokaci. Kyakkyawan ƙira, aiki mai hankali, da kulawa na yau da kullun suna sa injunan aiki ya daɗe. Masu aiki yakamata su duba saituna, tsabtace sassa, kuma su ɗauki kayan da suka dace. Waɗannan matakan suna sa sake yin amfani da su ya zama santsi kuma mafi inganci.

FAQ

Ta yaya ganga dunƙule guda ɗaya na JT ke taimakawa rage lokacin na'ura?

JT guda dunƙule ganga yana amfanim kayanda kuma sutura na musamman. Waɗannan fasalulluka suna taimaka wa ganga ya daɗe kuma yana ci gaba da aiki tare da ƙarancin tsayawa.

Wadanne robobi na JT guda dunƙule ganga zai iya aiwatar?

Masu aiki za su iya amfani da ganga guda na JT tare da robobi da yawa. Yana aiki da kyau tare da PE, PP, PS, PVC, PET, PC, da PA.

Sau nawa ya kamata masu aiki su duba ganga mai dunƙule guda ɗaya?

Masu aiki su duba ganga kowane mako. Binciken akai-akai yana taimakawa wajen gano matsaloli da wuri da kuma kiyaye tsarin sake amfani da su cikin santsi.

Lokacin aikawa: Juni-27-2025