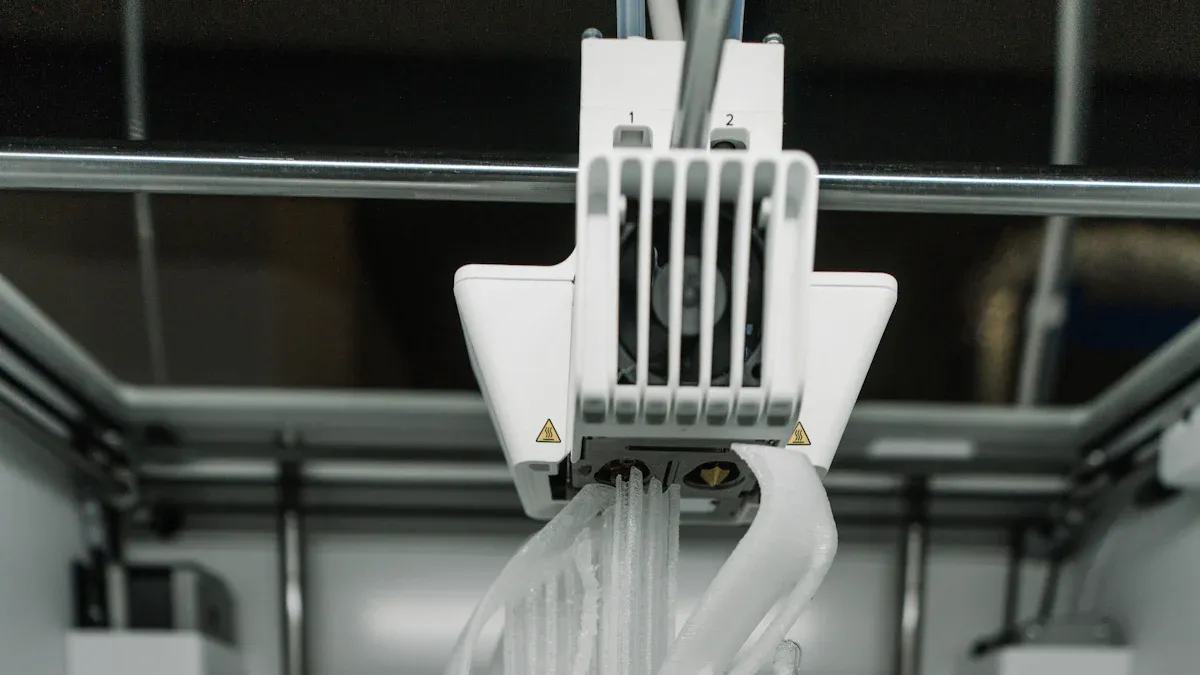

Extrusion dunƙule guda ɗaya yana amfani da dunƙule dunƙule guda ɗaya, yayin da extrusion ɗin tagwayen dunƙule ya dogara da sukurori biyu masu tsaka-tsaki don haɓaka haɗawa. Wannan bambanci yana rinjayar ingancin samfur da sarrafa tsari. Don samarwa mai sauƙi, mai girma, aRumbun Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙwaradace da mafi yawan bukatun.Twin Screw Extruder GangakumaTwin Screws Don Fitar Filastikyi fice a hadaddun hadaddun.

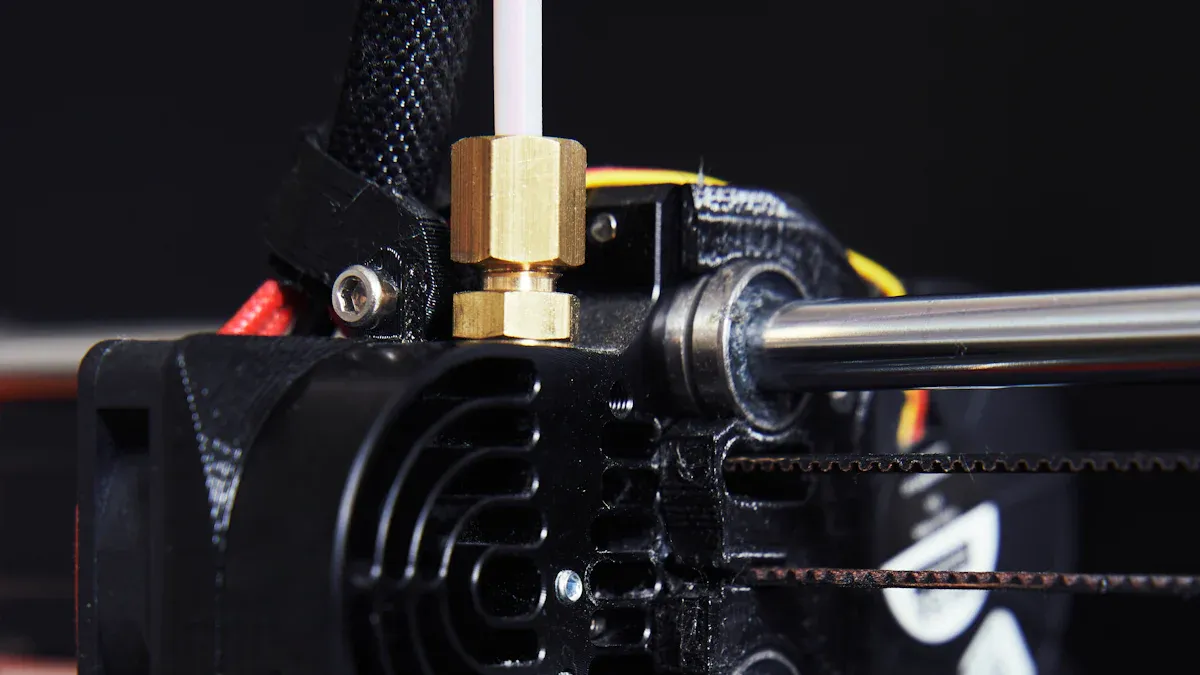

An Bayyana Extrusion Guda Daya

Yadda Single Screw Extrusion ke Aiki

Extrusion dunƙule guda ɗaya yana amfani da dunƙule mai juyawa guda ɗaya a cikin ganga mai zafi. Skru yana matsar da ɗanyen robobi ko roba gaba, inda yaƙe-yaƙe da zafi suka narke. Kayan da aka narke yana wucewa ta cikin mutu don samar da sifa mai ci gaba. Masu aiki suna sarrafa maɓalli na maɓalli kamar zafin jiki na ganga (yawanci 160-180 ° C), saurin dunƙulewa, da zafin jiki na mutuwa. Gudun naúrar ɗauka da zafin tankin ruwa suna taimakawa sarrafa diamita na samfurin ƙarshe da sanyaya. Skru yana aikimanyan ayyuka guda uku: isarwa, narkewa, da hadawa. Tsarin gangafasalulluka kamar matsananciyar fushi da plating chrome suna rage juzu'i da mannewa, suna tabbatar da aiki mai santsi.

Amfanin Extrusion Single Screw Extrusion

Masu kera zaɓeguda dunƙule extrusiondon saukinsa da ingancinsa. Zane yana ba da damar aiki mai sauƙi da kulawa. Ƙananan saka hannun jari na farko da farashin aiki sun sa ya zama abin sha'awa ga kamfanoni da yawa.Amfanin makamashiya yi fice, kamar yadda tsarin ke amfani da ingantattun dumama da ƙananan sassa masu motsi. Masu aiki zasu iya cimma daidaiton ingancin samfur ta hanyar daidaita yanayin zafi, matsa lamba, da saurin dunƙulewa. Tsarin yana ɗaukar nau'ikan albarkatun ƙasa, yana sa ya zama mai dacewa don buƙatun samarwa daban-daban.

Tukwici: Kulawa na yau da kullun da saka idanu na makamashi na ainihi na iya ƙara haɓaka inganci da ingancin samfur.

Iyaka na Single dunƙule extrusion

Extrusion dunƙule guda ɗaya yana fuskantar wasu ƙalubale. Abin da ake samarwa na iya zama mara ƙarfi a cikin manyan gudu masu yawa, yana iyakance ƙimar samarwa. Kula da zafin jiki na narkewa da samfuran kamanni na iya zama da wahala, musamman tare da hadaddun kayan. Tsarin na iya yin gwagwarmaya tare da ci-gaba cakuɗawa ko ƙira waɗanda ke buƙatar ingantaccen sarrafawa. Halin ciyarwa da kayan aiki suma sun dogara sosai akan ƙirar dunƙule da buɗaɗɗen lissafi.

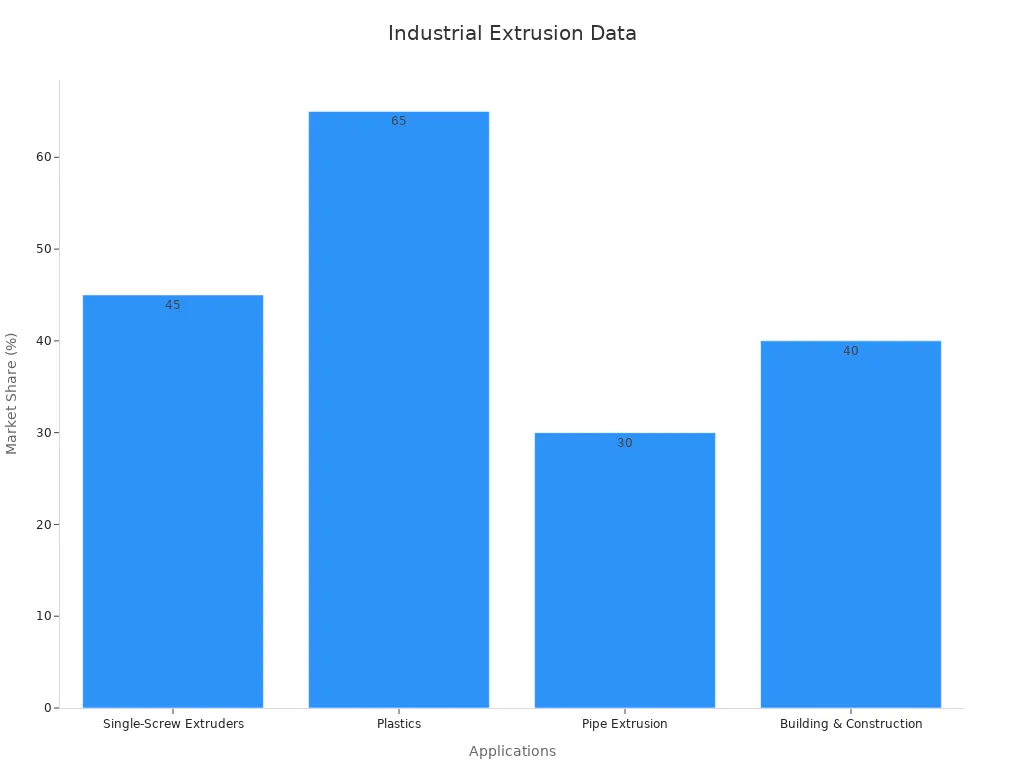

Aikace-aikace na yau da kullun na Extrusion Screw Single

Extrusion guda ɗaya yana samun amfani a masana'antu da yawa. Marufi yana jagorantar kasuwa, tare da kusan kashi 60%, samar da fina-finai da zanen gado daga polymers kamar PE, PP, da PVC. Sashin gine-gine yana amfani da shi don bututu da bayanan martaba, yayin da masu kera motoci ke dogaro da shi don sassan ciki da na waje. Likita, kayan masarufi, da masana'antun lantarki suma suna amfana da wannan fasaha.

| Nau'in Samfura | Diamita Maɗaukaki (mm) | L:D Rabo | Ƙarfin Mota (kW) | Ƙarfin fitarwa (kg/h) | Bayanan kula akan inganci da ka'idoji |

|---|---|---|---|---|---|

| Babban Haɓaka Single dunƙule | 60-120 | 38:1 | 110-315 | 465-1300 | 20-30% mafi girma; Siemens AC Motors, CE-certified |

| Madaidaicin Madaidaicin Guda Guda | 60-120 | 33:1 | 55-315 | 150-900 | Daidaitaccen kayan haɓaka inganci |

Bayanin Twin Screw Extrusion

Yadda Twin Screw Extrusion ke Aiki

Twin dunƙule extrusionyana amfani da kusoshi biyu masu tsaka-tsaki waɗanda ke juyawa cikin ganga mai zafi. Masu aiki suna ciyar da albarkatun kasa kamar pellets ko foda a cikin hopper. Sukurori suna matsar da kayan gaba, matsawa da cusa shi. Zafi daga ganga da gogayya daga sukurori narke kayan. Musamman dunƙule abubuwa cakude da homogenize da narke, tabbatar ko da watsawa Additives. Narkakkar kayan daga nan ta wuce ta mutu don samar da samfurin ƙarshe. Ganga mai ma'ana tare da wuraren dumama da sanyaya suna ba da damar sarrafa madaidaicin zafin jiki. Yankunan iska suna cire iska da rashin ƙarfi, haɓaka ingancin samfur.

Ƙarfin Twin Screw Extrusion

Twin screw extrusion yana ba da fa'idodi da yawa:

- Superior hadawa da homogenization saboda intermeshing sukurori.

- Ƙarfin ƙarfi mai ƙarfiinganta haɗakarwa da daidaiton samfur.

- Modular zane yana ba da damar daidaitawa sauƙi don kayan daban-daban.

- Ingantattun kula da zafin jiki yana rage lalatawar thermal.

- Babban kayan aiki da yawan aiki suna tallafawa masana'anta masu girma.

- Saitunan dunƙule masu sassaucin ra'ayi suna haɓaka aiki don polymers daban-daban.

- Kyakkyawan sarrafa tsari tare da daidaitawa mai zaman kansa na saurin dunƙule da zafin jiki.

- Rayuwar kayan aiki mai tsayi kamar yadda ake raba kaya tsakanin sukurori biyu.

| Bangaren Fasaha | Bayani |

|---|---|

| Babban Haɗin kai & Haɗuwa | Sukurori masu tsaka-tsaki suna haifar da juzu'i da tasiri don haɗawa iri ɗaya. |

| Babban Abun Kaya & Yawan Samfura | Juyawa masu juyawa suna ba da damar haɓaka ƙimar samarwa da inganci. |

| Yawanci | Iya sarrafa nau'ikan polymers da hadaddun tsari. |

Rashin raunin Twin Screw Extrusion

- Twin dunƙule extruders suna da hadaddun tsari da mafi girma farashi.

- Gudun abu a cikin extruder yana da wuyar ƙira da tsinkaya.

- Canje-canjen matsi na iya faruwa saboda juzu'i na juzu'i.

- Kula da girman barbashi da daidaiton tsari yana gabatar da ƙalubale.

- Haɓakawa daga lab zuwa samarwa yana buƙatar daidaitawa a hankali.

Amfanin gama gari don Twin Screw Extrusion

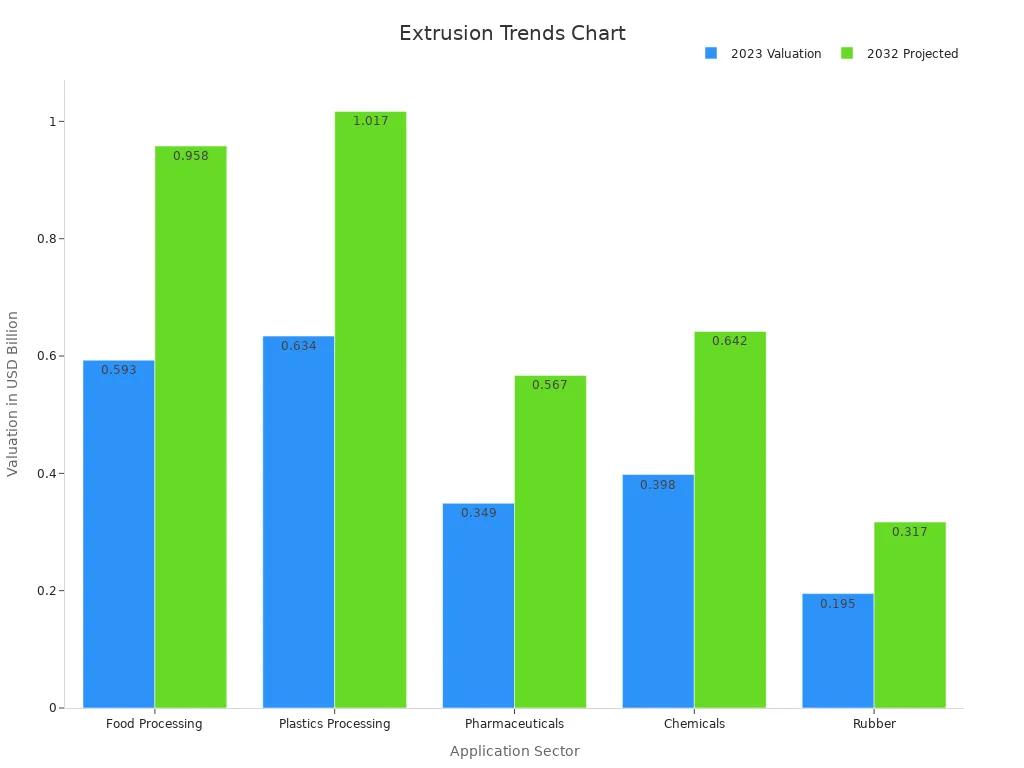

Twin dunƙule extruders suna taka muhimmiyar rawa a yawancin masana'antu. Masu kera suna amfani da su don haɗa robobi, sarrafa kayan da aka sake fa'ida, da kuma samar da bioplastics. Masana'antar abinci ta dogara da su don kayan ciye-ciye, hatsi, da abincin dabbobi. Kamfanonin harhada magunguna suna amfani da tagwayen dunƙule extrusion don yin ƙwaƙƙwaran nau'ikan sashi. Sassan sinadarai da roba suma suna amfana daga haɗewarsu da sarrafa su. Kasuwar tagwayen masu fitar da dunƙulewa na ci gaba da haɓaka, buƙatu a Asiya-Pacific, Turai, da Arewacin Amurka.

Extrusion Single Screw Extrusion vs Twin Screw Extrusion: Mahimman Kwatancen Maɓalli

bambance-bambancen ƙira da injina

Single dunƙule extrusionyana amfani da dunƙule mai juyawa guda ɗaya tare da ƙirar helical mai sauƙi. Wannan zane yana tura kayan gaba ta cikin ganga. Akasin haka, tagwayen dunƙule extruders suna da sukurori biyu masu tsaka-tsaki. Waɗannan sukurori na iya jujjuya su a wurare iri ɗaya ko akasin haka kuma galibi sun haɗa da tubalan murɗa don ingantacciyar haɗuwa. Teburin da ke ƙasa yana nuna manyan bambance-bambancen fasaha:

| Al'amari | Single Screw Extruder | Twin Screw Extruder |

|---|---|---|

| Zane Zane | dunƙule guda ɗaya mai jujjuyawa tare da tsari mai sauƙi mai saurin tura abu gaba. | Matsakaicin tsaka-tsaki guda biyu, mai yuwuwa haɗin gwiwa ko jujjuyawa, tare da rikitattun geometries gami da ƙullun tubalan. |

| Ƙarfin Cakuda | Ya dace da kayan haɗin kai da sauƙi mai sauƙi. | Babban hadawa saboda tsaka-tsakin sukurori, yana ba da damar mafi kyawun tarwatsa abubuwan ƙari da filaye. |

| Kayan aiki & Fitarwa | Gabaɗaya ƙananan kayan aiki da ƙimar fitarwa. | Mafi girma kayan aiki da fitarwa, dace da babban sikelin samarwa. |

| Kula da Zazzabi | Babban iko akan zafin jiki, saurin dunƙulewa, da matsa lamba na ganga. | Ingantattun tsarin zafin jiki tare da wurare masu dumama / sanyaya ciki tare da ganga. |

| Sarrafa kayan aiki | Mai inganci don thermoplastics, elastomers, da robobin da aka sake fa'ida tare da daidaiton ingancin samfur. | Mafi dacewa don babban danko, zafin zafi, da hadadden tsari masu buƙatar sarrafawa daidai. |

| Tsari Sassauci | Ƙananan sassauƙa, aiki mai sauƙi da kulawa. | Mafi girman sassauci saboda ƙirar dunƙule na zamani da sigogi masu daidaitawa. |

| Ƙarfin Ƙarfafawa | Iyakance keɓancewa da damar iyawa. | Ƙaddamarwa mai tasiri da devolatilization, mahimmanci don kula da inganci. |

| Misalai na Aikace-aikace | Fim ɗin filastik, bututu, haɗawa, murfin waya, extrusion takardar, sarrafa abinci. | Haɗaɗɗen polymer, sarrafa abinci, magunguna, da sarrafa abubuwa masu rikitarwa. |

Masu bincike kamar Shen et al. da Sastrohartono et al. sun nuna cewa tagwayen dunƙule extruders suna ba da ƙarin fasalulluka na ƙira, irin su mafi kyawun juzu'in juzu'i da ingantaccen kuzari, musamman don haɗaɗɗun kayan.

Haɗuwa da Ƙarfin sarrafawa

Ƙarfin haɗawa da sarrafawa sun ware waɗannan fasahohin biyu. Single dunƙule extrusion aiki da kyau ga sauki, kama kayan. Yana iya aiwatar da ayyukan haɗaɗɗiyar asali, amma yana gwagwarmaya tare da haɗaɗɗiyar ci gaba ko ƙirar ƙira waɗanda ke buƙatar ingantaccen sarrafawa. Twin dunƙule extruders sun yi fice wajen hadawa. Su intermeshing sukurori haifar da karfi karfi da kneading effects. Wannan aikin yana tabbatar da har ma da tarwatsewar abubuwan ƙari da filler, waɗanda ke da mahimmanci ga samfuran inganci. Masu aiki za su iya daidaita abubuwan dunƙule da ɓangarorin ganga don daidaita tsarin don kayan daban-daban. A sakamakon haka, tsarin dunƙule tagwaye suna tallafawa hadaddun girke-girke da buƙatun samarwa.

Lura: Ga masana'antun da ke buƙatar haɗakar da polymers da yawa ko ƙara filaye, tagwayen dunƙule extruders suna ba da fa'ida fa'ida a cikin haɗakar aiki.

Abun amfani da inganci

Abubuwan amfani da inganci suna taka muhimmiyar rawa wajen zaɓar tsakanin waɗannan tsarin. Single dunƙule extrusion yawanci yana ba da ƙananan kayan aiki, yana mai da shi dacewa da ƙananan maƙasudin samarwa. Yana aiki a hankali saurin sarrafawa kuma yana ba da tabbataccen sakamako don daidaitattun samfuran. Twin dunƙule extruders, a daya bangaren, samun mafi girma kayan aiki da kuma sauri sarrafa gudu. Suna goyan bayan manyan buƙatun iya aiki kuma suna kula da ingancin samfur koda tare da hadaddun granulation. Teburin da ke ƙasa yana kwatanta ma'auni masu mahimmanci:

| Ma'auni | Single Screw Extruder | Twin Screw Extruder |

|---|---|---|

| Kayan aiki | Ƙananan kayan aiki, dace da ƙananan maƙasudin samarwa | Mafi girma kayan aiki, dace da manyan buƙatun iya aiki |

| Gudun sarrafawa | Gudun sarrafawa a hankali | Gudun sarrafawa da sauri |

| Ingancin samfur | Ƙarfin haɗuwa mai iyaka, ƙarancin hadaddun granulation | Haɗin haɓakawa, yana goyan bayan hadaddun granulation |

| Farashin Aiki | Ƙananan farashin aiki saboda sauƙi da ingantaccen makamashi | Haɓaka farashin aiki saboda rikitarwa da kulawa |

| sassauci | Ƙananan sassauƙa, aiki mafi sauƙi | Mafi girman sassauci, zai iya ɗaukar hadaddun tsari |

| Yawan fitarwa | Gabaɗaya ƙananan ƙimar fitarwa | Mafi girman ƙimar fitarwa |

Twin dunƙule extruders sau da yawa bayar da hujjar mafi girma halin kaka na aiki tare da ƙãra yawan aiki da kuma ikon rike mafi kalubale kayan.

Sassautu da juzu'i

Sassauci da haɓakawa suna da mahimmanci don masana'anta na zamani. Extrusion dunƙule guda ɗaya yana ba da ingantaccen aiki don daidaitattun samfura da kayan aiki. Koyaya, yana ba da iyakanceccen sassauci lokacin canzawa tsakanin tsari daban-daban ko nau'ikan samfuri. Twin dunƙule extruders sun yi fice a wannan yanki. A K 2016 cinikayya nuni, ci-gaba tagwaye dunƙule Lines sun nuna saurin canji tsakanin kayan, launuka, da kauri. Wasu tsarin sun canza tsari a cikin mintuna, ba sa'o'i ba. Wadannan masu fitar da kaya sun sarrafa fina-finai masu yawa tare da har zuwa yadudduka 11, kayan aiki kamar EVOH, nailan, da nau'o'in polyethylene daban-daban. Bayanan samarwa sun nuna a45.8% raguwar sharar kayan abuda kusan 29% tanadin makamashi bayan haɓakawa zuwa tsarin dunƙule tagwaye masu sassauƙa. Hakanan an rage yawan dawowar lokacin saka hannun jari da sama da kashi 26%. Waɗannan haɓakawa suna nuna fa'idodin aiki na tagwayen dunƙule extruders a cikin hadaddun, mahalli na abubuwa da yawa.

La'akarin Kuɗi da Kulawa

Kudin kuɗi da kulawa suna tasiri ga yanke shawara na ƙarshe don masana'antun da yawa. Tsarin dunƙule extrusion guda ɗaya yayi ƙasa da siye da aiki. Tsarin su mai sauƙi yana nufin ƙananan sassa don kulawa da rage yawan amfani da makamashi. Kulawa na yau da kullun yana da sauƙi, kuma lokacin raguwa ya kasance kaɗan. Twin dunƙule extruders na bukatar mafi girma zuba jari na farko. Tsarinsu mai rikitarwa da abubuwan ci-gaba suna haifar da haɓaka buƙatun kulawa da amfani da makamashi mafi girma. Koyaya, ga kamfanonin da ke samar da kayayyaki masu ƙima ko sarƙaƙƙiya, fa'idodin sassauƙa, kayan aiki, da inganci galibi sun fi ƙarin farashi. Zaɓin tsarin da ya dace ya dogara ne akan daidaita waɗannan abubuwan tare da burin samarwa da kasafin kuɗi.

Zaɓan Madaidaicin Extruder don Bukatun ku

Dacewar Abu

Zaɓan madaidaicin extruder yana farawa tare da fahimtar daidaituwar abu. Mahimman abubuwan na'ura kamargudun dunƙule, diamita, da tsawon-zuwa diamita raboyana shafar yadda mai fitar da kayan aiki daban-daban ke aiwatar da kyau. Misali, madaidaitan L/D mafi girma suna taimakawa tare da hadaddun kayan da ke buƙatar narkewa sosai da haɗuwa. Ƙirar ganga, gami da yankunan zafin jiki da iska, suna goyan bayan abubuwa masu mahimmanci ko sake yin fa'ida. Sharuɗɗan masana'antu sun ba da shawarar daidaita mai fitar da kayan zuwa yanayin sarrafa kayan, danko, da yawan kwarara. Extrusion dunƙule guda ɗaya yana aiki da kyau don sarrafa dumbin thermoplastics, yayin da tagwayen dunƙule extruders ke ɗaukar hadadden tsari a cikin masana'antar abinci, magunguna, da masana'antar polymer.

Sikelin samarwa da fitarwa

Ma'aunin samarwa da buƙatun fitarwa suna taka muhimmiyar rawa a zaɓin extruder. Yawan fitarwa mafi girma na iya ƙara yawan amfani da makamashi da bukatun kulawa. Tsarin dunƙule na yau da kullun yana ba da izini don ingantaccen haɓakawa da aiki. Bincike ya nuna cewafitarwa da cika matakin tasiri ingancin samfur da ingantaccen hadawa. Manyan extruders suna buƙatar daidaita sigogin aiki a hankali don kiyaye ingantaccen sakamako. Kamfanoni dole ne su daidaita manufofin samarwa tare da farashin aiki da rikitaccen fasaha.

Abubuwan Kasafin Kudi da Kuɗi

La'akarin farashi ya haɗa da na gaba da ciyarwa mai gudana. Teburin da ke ƙasa yana zayyana mahimman abubuwan farashi:

| Factor Factor | Bayani | Tasirin Budget |

|---|---|---|

| Siyan Farko | Ya bambanta da girma da nau'in | Manyan zuba jari na gaba |

| Takaddun shaida | ISO 9001, CE, da dai sauransu. | Zai iya ƙara farashin sayayya |

| Kulawa | Ana buƙatar sabis na yau da kullun | Kudin shekara mai gudana |

| Amfanin Makamashi | Ingantattun samfura suna adana farashi na dogon lokaci | Mafi girma a gaba, ƙananan kowane wata |

| Horowa | Ana buƙatar aiki mai kyau | 1-3% na farashin sayayya |

Masu masana'anta a Asiya-Pacific galibi suna amfana daga ƙananan farashin aiki saboda fa'idodin yanki.

Shawarwari na tushen aikace-aikace

Yaushezabar tsarin extrusion, kamfanoni yakamata suyi la'akari da ƙarar samarwa, sassaucin mai siyarwa, da buƙatun inganci. Don samfurori na asali da ƙananan gudu, ƙaddamarwar dunƙule guda ɗaya yana ba da sauƙi da ƙananan farashi. Twin dunƙule extruders sun dace da babban girma, hadaddun, ko sabbin samfura waɗanda ke buƙatar haɓakar haɗawa da sassauci. Masana'antu irin su kera motoci, abinci, da magunguna galibi sun fi son tsarin tagwaye don dacewarsu da ingancin samfura. Kamfanonin da ke neman bambance-bambancen kasuwa na iya canzawa zuwa tagwayen dunƙulewa don cimma abubuwan samfur na musamman.

- Twin dunƙule extrudersyi amfani da sukurori biyu don ingantaccen haɗawa da kwararar kayan abu.

- Suna sarrafa ƙarin nau'ikan kayan aiki kuma suna ba da babban aiki.

- Extrusion dunƙule guda ɗaya yana aiki mafi kyau don sauƙi, ƙarancin danko.

- Don hadaddun samfura ko inganci mafi girma, kamfanoni yakamata su zaɓi tagwayen dunƙule extruders.

FAQ

Menene babban bambanci tsakanin dunƙule guda ɗaya da extrusion dunƙule tagwaye?

Extrusion dunƙule guda ɗaya yana amfani da dunƙule ɗaya don aiki na asali. Twin dunƙule extrusion yana amfani da sukurori biyu don ingantacciyar haɗawa da sarrafa kayan hadaddun.

Wanne extruder ne ya fi dacewa don sake amfani da robobi?

Twin dunƙule extruders suna sarrafa robobin da aka sake sarrafa su da kyau. Suna samar da mafi kyawun haɗuwa da sarrafawa, wanda ke inganta ingancin samfurin.

Yaya aka kwatanta kulawa tsakanin nau'ikan biyu?

Masu fitar da dunƙule guda ɗaya suna buƙatar ƙarancin kulawa.Twin dunƙule extruders suna buƙatar ƙarin kulawasaboda hadaddun tsarin su da ƙarin sassa.

Lokacin aikawa: Jul-08-2025