Ganga mai yin gyare-gyare na filastik yana taka rawa sosai wajen tsara ingancin narkewa da saurin samarwa. Injiniyoyin sun mayar da hankali kanGanga Gyaran alluraƙira don haɓaka aiki. Suna amfani da kayan daban-daban donInjin Screw Plastic Extruder MachinekumaSingle dunƙule Extrusion Machine. Kowane zaɓi yana taimakawa inji sarrafa robobi da kyau.

Filastik Injection Molding Screw Barrel Tsarin da Ayyuka

Nau'in Ganga: Bimetallic vs. Integral

Zaɓin nau'in ganga mai kyau na iya yin babban bambanci a yadda aFilastik Allurar gyare-gyaren dunƙule gangayayi. Ganga-gangan bimetallic suna amfani da tushe mai ƙarfi na ƙarfe tare da rufin gami mai tauri a ciki. Wannan zane yana adana kayan aiki masu mahimmanci kuma yana barin masana'antun su maye gurbin sawa kawai, wanda ya sa kulawa ya fi sauƙi kuma mafi tsada. Matsakaicin da ke tsakanin rufin da ganga dole ne ya zama daidai don kiyaye zafi yana gudana cikin sauƙi da hana motsi. Ganga na Bimetallic suna aiki da kyau don sarrafa robobi masu ƙyalli ko ƙarfafawa saboda suna ƙin lalacewa kuma suna daɗe.

An yi ganga masu haɗaka a matsayin guda ɗaya. Wannan yana ba su daidaitattun daidaito har ma da rarraba zafi tare da ganga. Suna sauƙaƙe shigarwa da kula da tsarin dumama da sanyaya. Koyaya, suna buƙatar tsauraran sarrafa masana'anta don kiyaye ingancin inganci. Lokacin kwatanta biyun, ganga masu haɗaka suna ba da kulawa mai sauƙi da dumama iri ɗaya, yayin da ganga na bimetallic suna ba da mafi kyawun juriya da maye gurbin sashi.

| Yanayin Aiki | Hadakar Ganga | Ganga Bimetallic |

|---|---|---|

| Gina | Single-yanki, high masana'anta daidaici | Base ganga tare da maye gami karfe bushing |

| Rarraba Zafi | Rarraba zafi na Uniform tare da axis ganga | Ana ci gaba da gudanar da zafi idan yanayin bushewa ya yi daidai |

| Saka Resistance | Daidaitaccen lalacewa juriya | Ingantattun juriya na lalacewa saboda rufin ƙarfe na gami |

| Kulawa | Sauƙaƙan shigarwa da kiyaye tsarin dumama / sanyaya | Mai maye gurbin bushewa yana ba da damar sauya sashi mai sauƙi |

| Amfanin Kayayyaki | Yana buƙatar mafi girman daidaito da ingancin kayan aiki | Yana adana abubuwa masu mahimmanci ta amfani da ƙarfe mai ƙarfe kawai a cikin rufi |

Gangunan bimetallic sau da yawa suna daɗe da yawa fiye da ganga na haɗin gwiwa, musamman lokacin sarrafa kayan tauri. Tsarin su yana rage raguwar lokaci da farashin canji, wanda ke taimakawa ci gaba da samar da aiki lafiya.

Matsakaicin Geometry: Rabo L/D, Matsakaicin Ratio, da Tsarin Jirgin sama

Geometry nadunƙule a cikin wani Filastik Injection gyare-gyaren dunƙule gangayana siffanta yadda robobi ke narkewa da haɗuwa. Matsakaicin L/D, wanda ke kwatanta tsayin dunƙule zuwa diamita, yana shafar daidaituwar narkewa da haɗuwa. Matsakaicin tsayi mai tsayi (mafi girman L/D rabo) yana ba filastik ƙarin lokaci don narkewa da haɗuwa, wanda ke haɓaka ingancin samfur. Duk da haka, idan dunƙule ya yi tsayi da yawa, zai iya haifar da lalacewar thermal, musamman tare da robobi masu zafi. Kayan aiki kamar PVC da POM suna buƙatar guntun sukurori don guje wa lalacewa, yayin da gilashin da ke cike da gilashi ko babban danko suna amfana daga screws masu tsayi da kuma ƙarfafa wuraren haɗuwa.

- Kayayyakin da ke da kwanciyar hankali mai kyau suna amfani da dogon sukurori don ingantacciyar haɗuwa.

- Filastik masu zafin zafi suna buƙatar guntun sukurori ko ƙirar zaren musamman.

- Babban manufar sukurori (L/D ~ 20:1) sun dace da robobi na kowa amma suna iya nuna bambancin launi.

- Masu shinge shinge (L / D ~ 24: 1) inganta haɗuwa don ƙarfafa robobi.

- Rarraba sukurori (L / D ~ 18: 1) taimakawa kayan da ke da zafi don guje wa lalacewa.

- Haɗa sukurori (L/D ~ 22:1) suna ba da narke iri ɗaya don robobi na musamman.

Matsakaicin matsi yana auna nawa dunƙule ya matsa robobin. Manyan robobi masu danko suna buƙatar matsi mafi girma don narkewa da haɗuwa da kyau. Daidaita rabon matsawa yana taimakawa ma'auni na kayan aiki da ingancin samfur. Masu sana'a galibi suna saka idanu da haɓaka ƙirar dunƙule don dacewa da bukatun kayan.

Tsarin jirgin sama yana da mahimmanci. Ingantattun sukurori na rheologically suna haɓaka ingancin narkewa ta hanyar daidaita yanayin kwararar polymer. Tsarin Isar da Narke Sarrafa yana taimakawa sarrafa zafin narke da danko, rage haɗarin lalacewa. Haɗuwa da sukurori da ƙwanƙwasa shinge mai ƙarfi suna ba da narke iri ɗaya kuma suna hana matattun tabo, wanda ke hana robobin yin zafi ko canza launin.

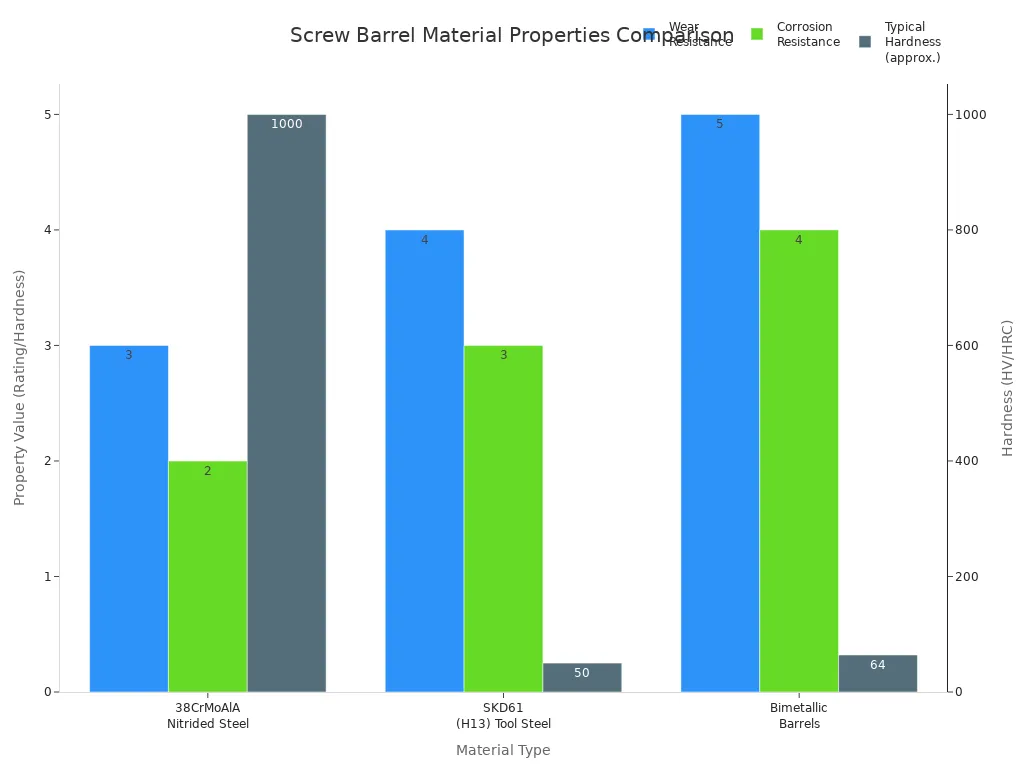

Haɗin Kayan Abu da Magungunan Sama

Kayayyakin da ake amfani da su don yin gyare-gyaren gyare-gyaren gyare-gyaren gyare-gyaren filastik suna shafar tsayin daka da aikin sa. Karfe na Nitrided yana ba da tauri mai kyau da juriya don daidaitattun robobi. Ganga-gangan bimetallic sun haɗu da tushe na karfe tare da layin alloy, yana ba da kyakkyawan lalacewa da juriya na lalata ga robobi masu tauri ko cike. Karfe na kayan aiki yana ba da ƙarfi mai ƙarfi da juriya ga matsanancin yanayi.

| Nau'in Abu | Kayayyakin Maɓalli & Ribobi | Fursunoni & Iyakance | Mafi kyawun Aikace-aikace |

|---|---|---|---|

| Nitrided Karfe | High surface taurin; juriya mai kyau ga resin da ba a cika ba; mai araha | Rashin juriya na lalata; bai dace da resin abrasive/chemical | Abubuwan resins kamar polyethylene, polypropylene |

| Ganga Bimetallic | Ƙarfe goyon baya tare da alloy liner; kyakkyawan lalacewa da juriya na lalata; tsawon rayuwa | Mafi tsada; na iya zama overkill don amfanin gaba ɗaya | Gilashin da aka cika da nailan, ABS mai ɗaukar harshen wuta, PVC, polymers masu ƙarfi |

| Alloys na tushen nickel | Juriya na musamman na lalata; mai kyau ga harshen wuta-retardant da halogenated resins | Ƙarƙashin ƙarfi fiye da alluran tushen ƙarfe; ƙananan juriya na lalacewa | Chemically m polymers |

| Ƙarfe-Ƙarfe | Babban taurin da juriya | Ƙarƙashin juriya na lalata fiye da abubuwan da ke tushen nickel | Abrasive, mai cike da resins sosai |

| Kayan aiki Karfe | Tauri da ƙarfi na musamman; high lalacewa juriya | Babban farashi; mai saukin kamuwa da lalata ba tare da sutura ba | Matsanancin yanayin lalacewa, aikace-aikacen fitarwa mai girma |

| Ganga Masu Rufe Na Musamman | Rubutun kamar tungsten carbide ko chrome plating suna inganta lalacewa da juriyar lalata | Yana ƙara farashi da rikitarwa; shafi mannewa dabam | Aikace-aikacen guduro na al'ada ko m |

Jiyya na saman kamar nitriding da chrome plating suna haɓaka juriya da tsawon rayuwa. Nitriding na iya ninka ko sau uku rayuwar sabis na sukurori da ganga. Chrome plating yana ƙara taurin da juriya na lalata, amma nitriding sau da yawa yana aiki mafi kyau a ƙarƙashin yanayin abrasive. Fesa Molybdenum tare da nitriding yana ba da ƙarin kariya. Yin aiki da kyau da kulawa suna taimakawa haɓaka waɗannan fa'idodin.

Tashar Ciyarwa da Zane-zane

Tsarin tashar tashar ciyarwa yana sarrafa yadda filastik ke shiga ganga. Kyakkyawan kula da zafin jiki a tashar ciyarwa yana kiyaye dankon kayan ya tsaya tsayin daka, wanda ke taimakawa ci gaba da gudana da kuma ciyarwa. Masu ɗaukar hoto da masu karɓar hopper suna tabbatar da cewa abu yana motsawa cikin sauƙi cikin injin, yana rage ƙazanta da zubewa. Wannan saitin yana kiyaye ingancin samarwa da daidaiton ciyarwa.

- Masu ɗaukar injina suna hawa kai tsaye akan maƙogwaron inji, suna rage gurɓatawa.

- Masu karɓar hopper suna amfani da nauyi don ciyar da abu, sauƙaƙe tsari.

Zane-zanen iska yana taka muhimmiyar rawa. Screws suna da yankuna na musamman waɗanda ke cire danshi da rashin ƙarfi yayin aiki. Wannan yana da mahimmanci ga kayan hygroscopic da robobi da aka sake yin fa'ida. Tashar jiragen ruwa masu iska suna barin iskar gas da danshi su tsere, yana hana lahani da kiyaye ingancin extrusion mai girma.

Tukwici: Ingantacciyar tashar ciyarwa da ƙirar iska tana taimakawa ci gaba da samarwa da haɓaka ingancin samfur, musamman lokacin aiki tare da robobi da aka sake sarrafa su ko kuma masu mahimmanci.

Sakamakon Aiki na Filastik Injection Molding Screw Barrel Design

Narke Quality da Homogeneity

Kyakkyawan ƙera Filastik Injection gyare-gyaren dunƙule ganga yana taimakawa ƙirƙirar santsi har ma da narkewa. Geometry na dunƙule, gami da nasarabon matsawada kuma siffar shiyyoyin sa, suna sarrafa yadda robobin robobi ke narkewa da gaurayawa. Lokacin da rabon matsawa ya dace da kayan, narke yana gudana daidai. Wannan yana rage matsaloli kamar alamar splay ko narkewar da ba ta cika ba. Theyankin ciyarwayana motsawa da dumama pellets, yankin matsawa yana narkewa kuma yana danna kayan, kuma yankin metering yana tabbatar da narke ko da. Siffofin kamar zurfin tashoshi da sassan haɗawa suna taimakawa zafi mai zafi da haɗa filastik. Masu shingen shinge na iya raba robobi mai ƙarfi da narke, yana sa narkewa ya fi dacewa da ceton kuzari.

Lokacin da narke ya kasance iri ɗaya, samfurin ƙarshe ya fi kyau kuma yana aiki mafi kyau. Cakuda mara kyau na iya haifar da ɗigon launi, tabo mara ƙarfi, ko canje-canje a girman sashi. Kyakkyawan narke homogeneity yana nufin ƙarancin lahani da ƙarin abin dogaro. Masu aiki kuma za su iya amfani da na'urori masu auna firikwensin don kallon ingancin narkewa da daidaita saituna don ingantacciyar sakamako.

- Rashin narkewar narkewa yana haifar da ɗigon launi da raunin rauni.

- Kyakkyawan narkewa yana haifar da daidaiton girman sashi da ƙarfi.

- Ingancin narkewa ya dogara da zafin ganga, saurin dunƙulewa, da matsi na baya.

Lura: Tsayawa yanayin zafi na narkewa da daidaita ƙirar dunƙule zuwa nau'in filastik yana taimakawa guje wa lahani da kiyaye ingancin samfur.

Haɗin Haɓakawa da Lokacin Zagayowar

Haɗin haɗawa ya dogara da siffar dunƙule da fasali na musamman. Yayin da dunƙule ke juyawa, yana turawa da naɗe robobin, yana haifar da ƙarfikarfi karfi. Haɗin sassan kusa da tip, kamar fil ko jiragen shinge, suna taimakawa gauraya narke. Wannan aikin yana yada launi da ƙari daidai gwargwado, don haka ɓangaren ƙarshe ya dubi santsi da uniform. Masu shingen shinge suna amfani da jirgi na biyu don raba robobin da aka narkar da daskararru, suna saurin narkewa kuma suna hana kutsawa marasa narkewa.

- Screw geometry yana sarrafa yadda pellets ke motsawa, narkewa, da haɗuwa.

- Sassan haɗawa suna haifar da motsin madauki,hadawa sama da 95%na kayan da sauri.

- Masu shingen shinge da ƙira na musamman suna taimakawa tarwatsa launi da ƙari.

Haɗin haɗawa kuma yana shafar lokacin zagayowar. Mafi sauri kuma har ma da narkewa yana nufin injin zai iya yin ƙarin hawan keke cikin ƙasan lokaci. Amfani da sukurori, manyan diamita masu girma, ko tsagi mai zurfi yana ƙara saurin filastik. Haɓaka saurin dunƙule (lokacin da lafiya ga kayan) da rage matsa lamba na baya kuma na iya rage lokutan zagayowar. Babban tsarin dumama da sanyaya yana kiyaye ganga a daidai zafin jiki, yana taimakawa sassa suyi sanyi da sauri da kuma ci gaba da motsi.

- Ingantacciyar ƙirar ganga mai dunƙulewa tana hana toshewa da jinkiri.

- Daidaitaccen tsarin dumama da sanyaya suna taimakawa sassa su ƙarfafa da sauri.

- Kayan aiki masu ɗorewa da sutura suna rage raguwa don gyarawa.

Saka Juriya da Kulawa

Wear babban damuwa ne ga kowane ganga mai gyare-gyaren filastik allurar. Filaye masu ƙyalli, robobi masu lalata, da tsayin daka na samarwa na iya lalata dunƙule da ganga. Nau'o'in sawa na yau da kullun sun haɗa da sawar manne, lalacewa, da lalata. Misali, lalacewa na lalacewa yana faruwa lokacin da masu cika ƙarfi kamar fiber gilashin shafa akan ƙarfe. Lalacewar lalacewa ta zo daga sinadarai a cikin robobi kamar PVC.

| Saka Makanikai | Bayani | Dabarun Rage Zane |

|---|---|---|

| Rigar mannewa | Tuntuɓi saman saman ƙarfe da kayan canja wuri. | Yi amfani da gawa mai ƙarfi, bincika maki, tabbatar da dacewa da kayan. |

| Abrasive Wear | Ayyukan shearing daga pellets ko fillers. | Yi amfani da gawa mai ƙarfi, guje wa abubuwan da za su lalata, kiyaye kayan abinci mai tsabta. |

| Lalacewa Wear | Harin sinadari daga wasu robobi. | Yi amfani da kayan da ke jure lalata, guje wa sinadarai masu tsauri. |

| Batutuwan daidaitawa | Kuskure yana haifar da shafa da rashin daidaituwa. | Tabbatar da madaidaiciya da daidaita daidai. |

Zaɓin kayan abu da jiyya na saman suna yin babban bambanci. Liquid nitriding yana ƙara taurin saman ƙasa da juriya. Gangan bimetallic tare da layukan layi na musamman sun daɗe, musamman tare da robobi masu tauri. Bincike na yau da kullun da kiyayewa na rigakafi, kamar tsaftacewa da duba jeri, suna taimakawa kama matsaloli da wuri. Babban rufi da sabbin abubuwa na iya tsawaita rayuwar ganga har zuwa 40%, rage farashin kulawa da rage raguwar lokaci.

- Mitar kulawa ya dogara da kayan ganga da sutura.

- Kulawa na rigakafi da dubawa na yau da kullun yana kara tsawon rayuwar ganga.

- Babban jiyya na saman ƙasa yana rage gyare-gyare da sauyawa.

Daidaituwa zuwa Kayayyaki da Aikace-aikace Daban-daban

Zane mai sassauƙan dunƙule ganga yana ƙyale masana'antun sarrafa nau'ikan robobi da yawa. Za'a iya canza lissafin juzu'i, kamar tsayi, farar, da zurfin tashoshi, don dacewa da kayan daban-daban. Manufa na gaba ɗaya, shinge, da haɗa sukurori kowanne yana aiki mafi kyau tare da wasu robobi. Tsarin sanyaya, kamar tashoshi na ruwa, kiyaye ganga a daidai zafin jiki na kowane abu.

- Zane mai dunƙulewa da lissafidaidaita robobi daban-daban.

- Tsarin sanyaya yana hana zafi fiye da kima.

- Ƙarfin ƙarfi mai ƙarfi da sutura suna ɗaukar yanayi mai wahala.

Zane-zane masu daidaitawa kuma suna sauƙaƙa sauyawa tsakanin ayyuka. Siffofin kamar adaftan cire haɗin haɗin kai da sauri da masu turawa na dunƙule suna taimaka wa masu aiki su canza sukurori cikin sauri. Gudanar da tsarin daidaitawa suna amfani da na'urori masu auna firikwensin da koyan injin don daidaita saituna a ainihin lokacin. Wannan yana rage sauye-sauye na hannu kuma yana haɓaka sauye-sauye, don haka samarwa na iya canzawa daga abu ɗaya ko samfur zuwa wani tare da ƙarancin lokaci.

Tukwici: Ƙirar ganga mai daidaitawa tana taimaka wa masana'antu sarrafa nau'ikan robobi da yawa da sauya ayyuka cikin sauri, kiyaye samarwa da sassauƙa da inganci.

Shirya matsala al'amurran da suka shafi Aiki gama gari

Ko da tare da mafi kyawun zane, matsaloli na iya faruwa. Abubuwan gama gari sun haɗa dawuce gona da iri, Matsalolin zafin jiki, toshewa, hayaniya, da kurakurai masu haɗa launi. Kowace matsala tana da nata dalili da mafita.

| Batun Aiki | Bayani da Alamomin | Dalilai da Mafita |

|---|---|---|

| Yawa mai yawa | Abubuwan leken asiri, rashin inganci, yanayin zafi, hayaniya | Yi amfani da ganga na bimetallic, gami da taurin fuska, tsaftacewa na yau da kullun, daidaita daidai |

| Tsarin Zazzabi | Canza launi, charring, kumfa, warping | Raba ganga zuwa yankuna, yi amfani da na'urori masu auna firikwensin, zafin jiki na sannu-sannu, jaket masu rufewa |

| Toshewa da Ginawa | Babban matsin lamba, ƙarancin kwarara, baƙar fata | Tsaftace tare da mahalli mai tsafta, saurin dunƙulewa mai kyau, ganga hatimi yayin raguwar lokaci |

| Surutu ko Jijjiga | Ƙarar ƙararrawa, girgiza, gogayya | Duba jeri, bearings, yi amfani da damping vibration, ware abubuwan da aka gyara |

| Haɗin Launi/Launi | Launuka masu launi, inuwa marasa daidaituwa, gurɓatawa | Yi amfani da mahadi masu tsafta, tsaftacewa na yau da kullun, inganta ƙirar dunƙule, injunan hatimi yayin rufewa |

Masu aiki zasu iya magance matsaloli da yawa ta bin wasu matakai masu mahimmanci:

- Haɓaka tsarin dunƙulewa da wuraren zafin ganga.

- Saka idanu da daidaita yanayin zafi da saurin gudu.

- Calibrate feeders da hana abin gada.

- Bincika dunƙule da ganga don lalacewa, musamman a wuraren da ake yawan damuwa.

- Yi amfani da gyare-gyaren tsinkaya don tsara gyare-gyare da rage raguwa.

- Ajiye abin zazzagewakuma sake gyara sau kaɗan kawai.

- Horar da masu aiki don gano alamun gargaɗin da wuri.

Lura:Tsaftacewa akai-akai, lubrication mai kyau, da kulawa da hankaliTaimaka wajen kiyaye ganga mai gyare-gyaren filastik allura yana gudana cikin tsari da tsawaita rayuwarsa.

Ƙirƙirar tsarin gyare-gyaren gyare-gyaren gyare-gyare na filastik yana haɓaka ingancin narke da rayuwar kayan aiki. Lokacin da masana'antun ke zaɓinNau'in ganga dama, dunƙule lissafi, da kayan, suna ganin kwarara mai santsi, ingantacciyar haɗuwa, da ƙarancin lahani. Kulawa na yau da kullun, gami da tsaftacewa da dubawa, yana sa injina ke aiki da kyau kuma yana rage farashi.

FAQ

Menene babban fa'idar ganga dunƙule bimetallic?

Ganga na Bimetallic suna ƙin lalacewa daga robobi masu tauri. Suna dadewa kuma suna rage raguwa don kulawa.

Sau nawa ya kamata masu aiki su duba ganga mai dunƙulewa?

Masu aiki yakamata su duba ganga mai dunƙule kowane wata. Binciken akai-akai yana taimakawa kama lalacewa da wuri da kuma ci gaba da ci gaba da aiki da injuna.

Shin ganga mai dunƙulewa zai iya yin aiki da nau'ikan robobi da yawa?

| Nau'in Ganga | Daidaitawa |

|---|---|

| Babban Manufar | Yayi kyau |

| Shamaki | Madalla |

| Hadawa | Yayi kyau sosai |

Ganga mai kyau na iya ɗaukar robobi da yawa, amma wasu kayan suna buƙatar fasali na musamman.

Lokacin aikawa: Agusta-25-2025