Wani dakin gwaje-gwaje guda dunƙule extruder yana amfani da dunƙule mai jujjuya don narkewa, gauraya, da siffata polymers a cikin ganga mai zafi. Masu bincike sun dogara dahuce guda dunƙule extruder, guda dunƙule inji, kumainjin granulator mara ruwadon cimma mafi kyau duka hadawa da aminci, tasiri aiki. Bincike ya nuna cewadunƙule gudun da zafin jikikai tsaye tasiri ingancin samfur da aminci.

Babban Abubuwan Haɓaka Na Keɓaɓɓiyar Screw Extruder

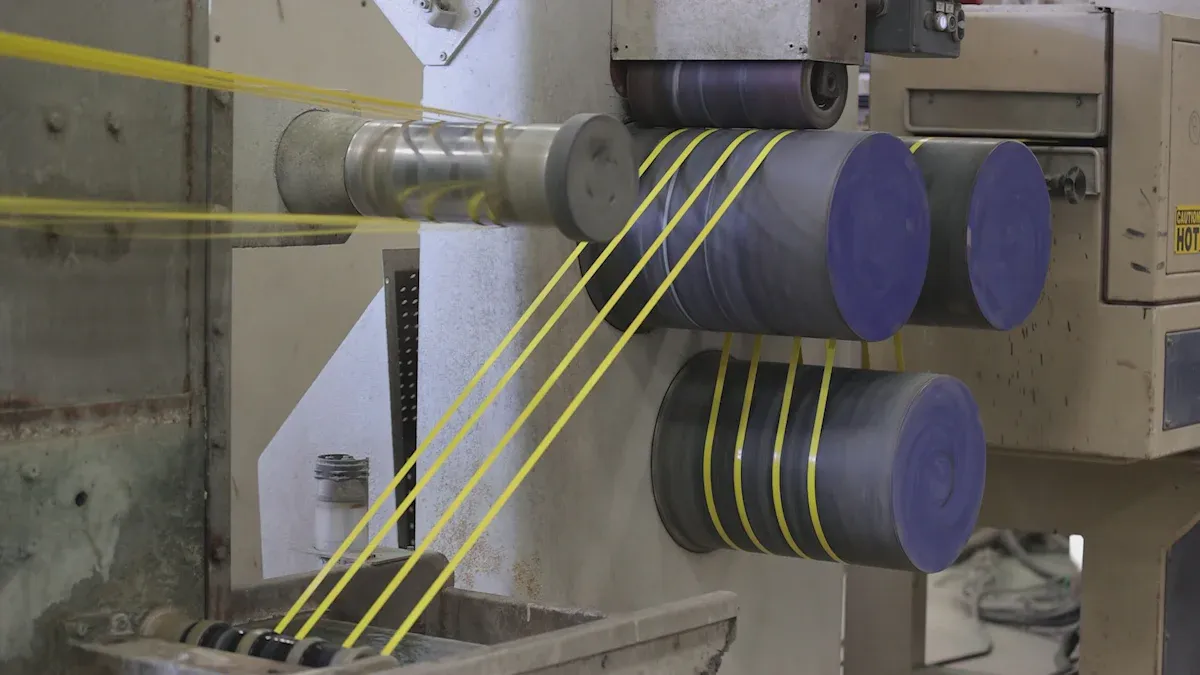

The Screw

A dunƙuleita ce zuciyar mai fitar da dunƙule guda ɗaya. Yana juya cikin ganga kuma yana motsa polymer gaba. Ƙunƙarar ta narke, haɗuwa, kuma tana tura kayan zuwa ga mutuwa. Zane mai dunƙule, gami da diamita, tsayin-zuwa diamita rabo, da matsi, yana shafar yadda polymer ɗin ke narkewa da haɗuwa. Ƙaƙwalwar ƙira mai kyau yana inganta ƙimar narkewa da inganci. Tsagi a kan dunƙule ko ganga na iya ƙara saurin narkewa kuma yana taimakawa sarrafa tsari. Gudun dunƙule kuma yana canza adadin haɗuwa da zafi da aka haifar.

Tukwici: Daidaita saurin dunƙulewa na iya taimakawa sarrafa zafin narke da ingancin samfur.

Ganga

Gangayana kewaye da dunƙule kuma yana riƙe da polymer yayin da yake motsawa. Ganga tana da wurare daban-daban na zafin jiki. Ana iya saita kowane yanki zuwa takamaiman zafin jiki don taimakawa narke polymer daidai. Misali, yankin farko na iya zama mai sanyaya don taimakawa wajen motsa daskararrun polymer, yayin da yankuna na baya sun fi zafi don narke kayan. Kula da zafin jiki mai kyau a cikin ganga yana da mahimmanci don kyakkyawan kwarara da ingancin samfur.Thermocouples suna auna zafin jiki a cikin gangadon kiyaye tsari tsayayye.

- Saitunan zafin jiki na ganga sun dogara da nau'in polymer da ƙirar dunƙule.

- Masu extruders na zamani galibi suna da yankuna uku ko fiye da yanayin zafi.

- Sashen ciyarwa ya kamata ya zama dumi amma kada yayi zafi sosai don gujewa manne kayan abu.

Tsarin dumama

Tsarin dumama yana kiyaye ganga a daidai zafin jiki. Ana sanya masu dumama tare da ganga kuma ana sarrafa su ta hanyar firikwensin. Tsarin zai iya daidaita kowane yanki don dacewa da bukatun polymer. Kyakkyawan sarrafa dumama yana taimakawa guje wa matsaloli kamar ƙona abu ko narke mara daidaituwa. Tsarin dumama yana aiki tare da tsarin kulawa don kiyaye tsari mai aminci da inganci.

The Die

Mutuwar tana siffanta polymer ɗin da aka narke yayin da yake barin maɗaurin dunƙule guda ɗaya. Ƙirar mutuƙar tana shafar siffar samfurin ƙarshe, samansa, da girmansa. Mutu mai kyau yana ba da santsi, har ma da gudana kuma yana taimakawa yin samfurori tare da ma'auni daidai. Dole ne mutun ya kula da madaidaicin zafin jiki da matsa lamba don guje wa lahani. Canje-canje a yanayin zafin mutu ko kwarara na iya canza ingancin samfurin.

- Gudun Uniform da ƙarancin matsa lamba a wurin fita mutuwa suna da mahimmanci ga inganci.

- Mutuwar geometry ta tashar da ma'aunin kwarara yana shafar daidaiton siffar samfur.

Tsarin Kulawa

Tsarin sarrafawa yana sarrafa aikin mai fitar da dunƙule guda ɗaya. Yana lura da zafin jiki, matsa lamba, saurin dunƙulewa, da ƙimar ciyarwa. Masu aiki suna amfani da tsarin sarrafawa don saitawa da daidaita sigogin tsari. Sa ido na ainihi yana taimakawa kiyaye tsari ya tsayayye da aminci. Hakanan tsarin sarrafawa na iya adana girke-girke na polymers daban-daban, yana sauƙaƙa maimaita gudu mai nasara.

Nau'in Screw Extruder guda ɗaya don Amfani da Laboratory

Saitunan dakin gwaje-gwaje na buƙatar nau'ikan extruders daban-daban don saduwa da takamaiman buƙatun bincike. Kowane nau'in yana ba da fasali na musamman da fa'idodi don sarrafa polymer.

Mai Haɓakawa Single Screw Extruder

Mai fitar da dunƙule guda ɗaya yana amfani da aƙirar dunƙule mataki biyu. Wannan ƙira yana rage karfin juyi da buƙatun ƙarfin doki yayin kiyaye fitarwa da saurin dunƙulewa. Tsarin iska yana cire danshi da gas daga narke polymer. Wannan mataki yana da mahimmanci don sarrafa robobin da ke sha ruwa. Cire waɗannan sauye-sauye yana hana lahani irin su splay da raunin injiniyoyi. Sau da yawa tashar jiragen ruwa tana aiki a ƙarƙashin vacuum, wanda ke taimakawa ƙaddamarwa ta hanyar rage matsa lamba. Sukullun mataki biyu kuma yana inganta haɗawa ta hanyar damfara da rage filastik. Wannan tsari yana haifar da ƙarin narke uniform. Masu aiki dole ne su daidaita abin da ake fitarwa tsakanin matakan biyu don guje wa zazzagewa ko hucewa ambaliya. Waɗannan fasalulluka suna sa fiɗa guda ɗaya mai fiɗa mai inganci kuma abin dogaro a aikace-aikacen dakin gwaje-gwaje.

Lura: Tsayayyen fitarwa da ƙananan amfani da makamashi sun ware masu fitar da su a cikin mahallin bincike.

Injin dunƙule guda ɗaya

Na'urar dunƙule guda ɗaya tana ɗaukar nau'ikan abubuwan fitar da abubuwa masu yawa don narkewa, haɗawa, da ƙirar polymers. Waɗannan injina suna ba da ƙira mai sauƙi da aiki mai sauƙi. Masu bincike na iya sarrafa tsagewa da zafin jiki da kyau, wanda ke taimakawa tare da ƙirar polymer na asali da ayyukan extrusion. Injin dunƙule guda ɗaya suna aiki da kyau don yin tubing, fim, da sauran samfuran sauƙi. Suna zuwa da girma dabam da kuma daidaitawa don dacewa da buƙatun bincike daban-daban.

| Nau'in Extruder | Key Features da Abvantbuwan amfãni | Aikace-aikace na yau da kullun da dacewa |

|---|---|---|

| Single Screw Extruders | Zane mai sauƙi, sarrafawa mai kyau, aiki mai sauƙi | Tubing, fim, asali polymer formulations |

| Twin Screw Extruders | Babban hadawa, m, tsaka-tsakin sukurori | Hadawa, hadaddun kayan aiki, magunguna |

| Miniature/Micro Extruders | Ƙananan sikelin, farashi-tasiri, abin dogara | R&D, samfuri, ƙayyadaddun samfuran kayan abu |

Injin Granulator mara ruwa

Injin granulator mara ruwa yana canza kayan filastik zuwa granules ba tare da amfani da ruwa ba. Wannan fasaha yana inganta ingantaccen makamashi kuma yana rage tasirin muhalli. Tsarin yana kiyaye granules bushe da tsabta, wanda ke amfana da ƙarin matakan sarrafawa. Injin granulator mara ruwa suna ɗaukar nau'ikan resin robobi da yawa. Suna taimaka wa masu bincike su samar da granules masu inganci don gwaji da haɓakawa.

Mataki-mataki Tsarin Fitar da Polymer

Ciyar da Kayan Polymer

Tsarin extrusion yana farawa tare da ciyar da albarkatun polymer a cikin hopper feed. Hopper yana tabbatar da ko da rarrabawa kuma yana hana toshewa, wanda ke taimakawa wajen ci gaba da samar da kayan aiki. Dunƙule a cikin ganga yana fara juyawa, yana jan pellet ɗin polymer ko foda a gaba. Zane na dunƙule, ciki har da diamita da tsayin daka zuwa diamita, yana taka muhimmiyar rawa a yadda kayan ke motsawa sosai. Tsarin sarrafawa yana ba masu aiki damar daidaita saurin gudu da ƙimar ciyarwa, wanda ke taimakawa daidaita tsarin don polymers daban-daban.

- An ƙera ƙwanƙolin ciyarwa don hana toshewa da tabbatar da ciyarwa mai santsi.

- Sukullun yana isarwa, matsawa, kuma ya fara zafi da polymer.

- Kula da zafin jiki a cikin ganga yana taimakawa inganta tsarin narkewa.

Nazarin farko sun tabbatar da cewa sarrafa saurin dunƙule da zafin jiki kai tsaye yana shafar yadda polymer ɗin ke ciyarwa da narkewa. Masu fitar da dakin gwaje-gwaje na zamani suna amfani da ingantattun sarrafawa don ci gaba da ciyar da inganci da kwanciyar hankali.

Narkewa da Filastik

Yayin da polymer ke motsawa tare da ganga, yana shiga wurare masu zafi. Zazzabi a kowane yanki yana ƙaruwa a hankali, yana haifar da polymer don yin laushi da narkewa. Jujjuyawar dunƙule da zafin ganga suna aiki tare don shafe kayan, tare da juya shi zuwa narkakkar iri ɗaya. Na'urori masu auna firikwensin da aka sanya tare da ganga suna lura da yanayin zafi da matsa lamba don tabbatar da cewa polymer ya narke a cikin kewayon sarrafa shi.

| Siga | Bayani |

|---|---|

| Narke Zazzabi | Dole ne ya kasance cikin kewayon sarrafa polymer don kyakkyawan sakamako. |

| Matsi Sama da Screw | Yana nuna ingancin narkewa da kwanciyar hankali. |

| Canjin Matsi | Ana sa ido don gano duk wata matsala tare da narkewa ko kwarara. |

| Sauyin yanayi | Ana bibiya don tabbatar da ko da dumama da kuma guje wa lahani. |

| Digiri na narkewa | An duba gani ko ta hanyar gwada fim ɗin da aka cire don tsabta da daidaito. |

| Fihirisar Ayyuka na Screw | Haɗa waɗannan abubuwan don ƙididdige ingancin narkewa daga matalauta (0) zuwa mafi kyau (1). |

Madaidaicin kula da zafin jiki da matsa lamba yana taimakawa hana lalacewa kuma yana tabbatar da daidaiton narkewa. Saka idanu na lokaci-lokaci tare da na'urori masu auna firikwensin ci gaba da fasaha na spectroscopy suna ba da ci gaba da bayanai, ƙyale masu bincike su daidaita saitunan kamar yadda ake bukata.

Hadawa da Isarwa

Da zarar narke, dole ne a haxa polymer sosai don tabbatar da daidaito. Zane-zanen dunƙule, gami da fasali kamar sassan shinge ko gaurayawan yanki, yana taimakawa haɗa kayan da cire duk wani guntu mai ƙarfi. Yayin da dunƙule ke juyawa, yana tura narkakkar polymer gaba, yana isar da shi zuwa ga mutuwa.

Masu bincike suna amfani da saitunan ci gaba tare daSamfurin tashoshin jiragen ruwa da na'urorin gano ganidon nazarin yadda kayan ke haɗuwa sosai. Ta hanyar allurar masu ganowa da auna yadda suke yaɗuwa, za su iya ganin yadda saurin dunƙulewa da lissafi ke shafar haɗawa. Babban gudun dunƙule wani lokaci na iya barin m gutsuttsura, amma musamman dunƙule kayayyaki inganta hadawa da kuma hana wannan batu.Na'urori masu auna matsi tare da gangaauna yadda polymer ke motsawa da kyau, yana taimakawa masu aiki su inganta tsarin.

Siffata Ta hanyar Die

Narkakkar polymer ya kai ga mutu, wanda ya siffata shi zuwa siffar da ake so. Zane na mutu yana ƙayyade girman samfurin ƙarshe da ingancin saman. Injiniyoyi suna amfani da kwaikwaiyon kwamfuta da bincike mai iyaka don ƙira mutun da ke samar da ingantattun siffofi da kuma rage lahani. Hakanan suna haɓaka juzu'i na tashar tashoshi don daidaita saurin gudu da rage bambance-bambancen tsarin kwayoyin halitta, wanda zai iya shafar girman samfurin.

| Bangaren Shaida | Bayani |

|---|---|

| Ƙarƙashin Ƙarƙashin Ƙarfafawa | An yi amfani da shi don nazarin kwarara da siffar daidaito a cikin mutu. |

| Ƙirƙirar Ƙira | Yana rage kurakurai kuma yana inganta daidaiton lissafi. |

| Tabbatar da Gwaji | Yana tabbatar da tsattsauran ikon girman samfur. |

| Kwaikwayo na Lambobi | Hasashen mutuwar kumbura da motsin mu'amala don ingantacciyar sakamako. |

| Sarrafa daidaitawar kwayoyin halitta | Ma'auni yana gudana don hana miƙewa mara daidaituwa da canje-canjen siffar. |

Daidaitaccen sarrafa kayan mutuwa da kayan aiki na ƙasa yana tabbatar da barin samfurinSingle Screw Extrudertare da daidai siffar da girman.

Sanyaya da Haɗewa

Bayan yin siffa, polymer mai zafi yana fita daga mutu kuma ya shiga lokacin sanyaya. Cooling yana ƙarfafa polymer, yana kullewa a cikin siffar ƙarshe da kaddarorinsa. Adadin sanyaya ya dogara da zafin jiki na extrusion, yanayin yanayi, da saurin da samfurin ke motsawa ta yankin sanyaya.

| Siga/Hani | Lura/Sakamako |

|---|---|

| Extrusion zafin jiki | Polymer extruded a 100 ° C |

| Yanayin yanayi | Ana kiyaye shi a kusa da 20 ° C yayin gwaje-gwaje |

| Matsakaicin yanayin sanyi | Kimanin 72 ° C |

| Tasirin saurin gudu | Ƙananan gudu suna jinkirin sanyaya kuma suna ƙara lokacin ƙarfafawa |

| Yanayin sanyi | Matsakaicin adadin yana raguwa yayin da saurin ya ragu; kololuwa yana canzawa zuwa lokaci mai tsawo |

| Tasirin Multi-Layer | Daga baya yadudduka na iya sake zafi na baya, inganta mannewa |

Kula da wuraren sanyaya a cikin kunkuntar kewayon zafin jiki, sau da yawa tsakanin ± 2°C, yana taimakawa tabbatar da daidaiton ingancin samfur. Kyakkyawan sanyaya yana hana warping kuma yana tabbatar da cewa polymer yana ƙarfafa daidai.

Aikace-aikace na Single Screw Extruder a cikin Binciken Polymer

Ƙirƙirar kayan aiki da Gwaji

Masu bincike suna amfani da masu fitar da dakin gwaje-gwaje don haɓakawa da gwada sabbin abubuwan haɗin polymer. Nazarin tushe da haƙƙin mallaka sun bayyana yaddadunƙule zaneda sarrafa zafi yana inganta narkewa da haɗuwa. Waɗannan haɓakawa suna taimaka wa masana kimiyya ƙirƙirar sabbin kayayyaki tare da takamaiman kaddarorin. Alal misali, wani ƙananan ƙarfin extruder da aka gina tare da kayan gida ya nuna aiki mai karfi a cikin samar da ma'auni. Ya sarrafa har zuwa kilogiram 13 a cikin awa daya kuma ya rage abubuwan da ba a so a cikin samfurin ƙarshe. Wadannan sakamakon sun tabbatar da cewa masu fitar da dakin gwaje-gwaje suna goyan bayan sabbin abubuwa da kuma kula da inganci a cikin tsara kayan.

| Siga | Daraja/Sakamako |

|---|---|

| Kayan aiki | 13.0 kg/h |

| Gudun dunƙulewa | 200 rpm |

| Diamita na Ganga | 40 mm |

| Rabon Faɗawa | 1.82-2.98 |

| Rage Inhibitor na Trypsin | 61.07% - 87.93% |

Inganta Tsari

Extruders na dakin gwaje-gwaje na taimaka wa masana kimiyya su sami mafi kyawun saitunan tsari don polymers daban-daban. Bayanan gwaji sun nuna hakanAmfani da makamashi ya dogara da saurin dunƙule da kaddarorin abu. Ta hanyar rikodin wutar lantarki da daidaita saitunan, masu bincike zasu iya inganta ingantaccen makamashi da ingancin samfur. Nazarin kuma ya nuna cewa canjidunƙule gudunda kuma ƙara wasu sinadaran na iya inganta yadda polymers ke haɗuwa da gudana. Waɗannan binciken suna taimaka wa ƙungiyoyi su kafa aminci, inganci, da matakai masu maimaitawa don duka bincike da samarwa.

Tukwici: Daidaita saurin dunƙule da zafin jiki na iya daidaita amfani da makamashi da haɓaka ingancin samfur.

Ƙirƙirar Ƙaramin-Sarancin Samfuri

Lab extruders suna sauƙaƙa ƙirƙirar ƙananan batches na sabbin samfura. Ƙungiya za su iya sarrafa zafin jiki, matsa lamba, da saurin dunƙule don samun ingantaccen sakamako. Wannan hanyar tana adana kuɗi kuma tana haɓaka haɓakawa. Masu bincike na iya gwada sabbin ra'ayoyi da sauri kuma su haɓaka masu nasara. Ƙaƙƙarfan extruders kuma suna ba da izinin sauye-sauye masu sassauƙa a cikin abu ko ƙira. Ci gaban da ake samu ta atomatik da saka idanu na lokaci-lokaci yana ƙara inganta tsarin sarrafawa da rage sharar gida.

- Madaidaicin iko akan sigogin tsari

- Ƙididdigar farashi da saurin samfur

- Sauƙaƙan daidaitawa don kayan daban-daban

- Ingantattun ingancin samfur da daidaituwa

Tips na Aiki da Shirya matsala don Single Screw Extruder

Saita Extruder

Saitin da ya dace yana tabbatar da ingantaccen aiki kuma yana ƙara rayuwar kayan aiki. Masu fasaha suna bin waɗannanmatakai don kyakkyawan aiki:

- Shigar da sukuroria cikin matsayinsu na asali kuma gwada sababbin sukurori a ƙananan gudu kafin cikakken aiki.

- Calibratesarrafa zafin jikikayan aiki akai-akai don daidaitawa daidai.

- Yi amfani da distilled ruwa a cikin tanki mai sanyaya don hana ƙima da duba matakan ruwa akai-akai.

- Bincika bawul ɗin solenoid da coils, maye gurbin kowane ɓangarori mara kyau.

- Tabbatar da amintattun ma'aurata kullun kuma tabbatar da cewa relays na yankin dumama da bawul ɗin solenoid suna aiki daidai.

- Tsabtace tankuna da wuraren shaye-shaye; maye gurbin sawa zoben rufewa kamar yadda ake buƙata.

- Bincika gogashin motar DC kuma ka kare daga tsatsa.

- Yi zafi a hankali yayin farawa kuma ƙara saurin gudu a hankali.

- Lubricate sassa masu motsi da ƙara matsawa akai-akai.

- Don ajiya na dogon lokaci, shafa man shafawa na anti-tsatsa da adana sukurori da kyau.

Tukwici: Bin waɗannan matakan yana taimakawa kiyaye ingancin samfur da tsawon kayan aiki.

Matsalolin gama gari da Mafita

Masu aiki na iya fuskantar matsaloli da yawa yayin aiki. Teburin da ke ƙasa yana zayyana matsalolin gama gari da mafita:

| Matsalolin Category | Batutuwan gama gari | Dalilai | Alamun | Magani |

|---|---|---|---|---|

| Kasawar Injini | Kulle makale | Gina kayan abu, mara kyau lube | Motoci da yawa, hayaniya | Tsaftace, mai mai, dubawa |

| Rashin Wutar Lantarki | Rashin gazawar mota | Yawan zafi, gajeriyar kewayawa | Babu farawa, zafi fiye da kima | Duba tsarin, kauce wa wuce gona da iri |

| Rashin Tsari | Rashin aikin filastik | Ƙarƙashin saurin gudu, yanayin zafi mara kyau | M surface, kumfa | Daidaita gudu, zafi, abu |

| Matakan rigakafi | Kulawa | Rashin tsaftacewa, dubawa | N/A | Jadawalin tsaftacewa, dubawa |

Binciken akai-akai da kulawa yana hana yawancin al'amura. Masu aiki yakamata su bi umarnin hannu lokacin da ake daidaita kashe extrusion don gujewa kuskure.

La'akarin Tsaro

Ayyukan extruder na dakin gwaje-gwaje ya ƙunshi haɗari da yawa. Matakan tsaro sun haɗa da:

- Saka kayan kariya na sirri kamar takalmi mai aminci da tabarau.

- Nisantar sutura mara kyau kusa da sassa masu motsi.

- Ƙaddamar da duk kayan lantarki ta ƙwararrun ma'aikata.

- Tsayar da benaye a bushe da amfani da dandamali ko magudanar ruwa don hana zamewa.

- Sanya masu gadi akan sassa masu motsi don kare hannu.

- Amfani da layin farawa don zaren zaren maimakon ciyar da hannu.

Lura: Ƙaƙƙarfan horo na aminci yana rage haɗarin ƙonawa, girgiza wutar lantarki, da raunin inji.

Laboratory extruders goyan bayan aminci, ingantaccen sarrafa polymer tadaidaitaccen sarrafa zafin jiki, matsa lamba, da saurin dunƙulewa. Masu bincike suna amfana da ƙananan samarwa, rage sharar gida, da saurin samfuri. Zane-zane na zamani yana ba da damar sauye-sauye masu sauri da gyare-gyare. Daidaitaccen aiki da hankali ga daki-daki yana taimakawa cimma ingantaccen sakamako da haɓaka ƙima a cikin binciken polymer.

FAQ

Wadanne nau'ikan polymers ne ke iya aiwatar da aikin dakunan gwaje-gwaje guda dunƙule extruder?

A dakin gwaje-gwaje guda dunƙule extruderna iya sarrafa yawancin thermoplastics, gami da polyethylene, polypropylene, polystyrene, da PVC. Masu bincike sukan zaɓi kayan bisa ga buƙatun aikin.

Ta yaya iska ke inganta ingancin polymer?

Fitar iska tana kawar da danshida gas daga polymer narke. Wannan matakin yana hana lahani, kamar kumfa ko tabo mai rauni, kuma yana haɓaka kayan injin na ƙarshe.

Ta yaya masu aiki ke sarrafa zafin extrusion?

Masu aiki suna saitawa da lura da yanayin yanayin ganga ta amfani da tsarin sarrafawa. Na'urori masu auna firikwensin suna ba da amsa na ainihi, suna ba da damar daidaitattun gyare-gyare don daidaitaccen narkewar polymer da siffa.

Lokacin aikawa: Jul-01-2025