Ƙararren Ƙararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwaƙwalwa na Ƙaƙwalwa na Ƙaddamarwa ya yi ya bambanta da yin gyare-gyaren allura saboda tsayinsa mai tsawo da girman matsi. Wannan yana taimakawa ƙirƙirar parisons iri ɗaya, wanda ke inganta tsabtar kwalba da ƙarfi. Yayin da kasuwar robobi ta duniya ke girma, daBusa Screw BarrelkumaFilm Blown Screwisar da ingantaccen narkewa, hadawa, da tanadin makamashi akanRumbun Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙwara.

Ayyukan Ganga mai dunƙulewa a cikin Tsarin Molding

Narkewar Abu Da Matsayin Badawa

Ganga mai dunƙule tana aiki azaman zuciyar duka kwalabe da injinan gyare-gyaren allura. Babban aikinsa shi ne narkar da pellet ɗin robobi da motsa narkakkar kayan gaba. A cikin gyare-gyaren allura, dunƙule yana juyawa cikin ganga mai zafi, yana matsawa da narkewar filastik. Da zarar robobin ya narke, dunƙule yana tura shi cikin wani tsari a babban matsi. Wannan tsari yana siffanta filastik zuwa sassa masu ƙarfi.

A cikin gyare-gyaren kwalabe, ganga mai dunƙule kuma yana narkar da polymer. Duk da haka, yadda yake motsa kayan zai iya canzawa. Alal misali, a cikin extrusion busa gyare-gyaren, dunƙule na iya juya ci gaba ko cikin matakai. Yana fitar da robobin da aka narke a matsayin bututu, wanda ake kira parison. Daga nan sai iska ta shiga cikin parison don samar da kwalba. A cikin gyaran gyare-gyaren allura, dunƙulewar tana allurar robobin da aka narkar a cikin wani tsari don yin preform, wanda daga baya ya zama kwalba. Ganga mai dunƙulewa tana daidaita rawar ta bisa tsarin gyare-gyare, amma koyaushe tana mai da hankali kan narkewa da motsa filastik yadda ya kamata.

Tukwici:Ganga mai ƙira mai kyau yana tabbatar da cewa filastik yana narkewa daidai kuma yana gudana lafiya, wanda ke taimakawa hana lahani a cikin samfurin ƙarshe.

Haɗuwa da Ciwon Masoya

Haɗuwa da kamanni suna taka rawa sosai a ingancin samfur. Ganga mai dunƙule dole ne ta haɗu da filastik da duk wani ƙari don haka ɓangaren ƙarshe ya yi kama da aiki kamar yadda aka zata. Daban-daban ƙira na dunƙule na iya canza yadda filastik ke haɗuwa. Misali, sukurori tare da tashoshi na musamman ko sassan haɗawa suna taimakawa rarraba masu launi da ƙari daidai gwargwado. Wannan yana haifar da mafi kyawun launi da ƙarancin rauni.

Masu kera sukan gwada yadda dunƙule ke haɗuwa ta hanyar duba yanayin zafi da launi na robobin da aka narkar. Suna neman ko da yanayin zafi da gauraye masu launi masu santsi. A ƙasadaidaitattun sabawaa cikin waɗannan gwaje-gwajen yana nufin mafi kyawun haɗuwa. Wasu ci-gaba na sukurori, kamar shinge ko ƙirar tashoshi masu yawa, suna nuna ingantattun haɗawa da ƙarin narke uniform. Waɗannan fasalulluka suna taimakawa ƙirƙirar kwalabe da sassa waɗanda suke da ƙarfi, bayyanannu, kuma ba su da ɗigo ko kumfa.

| Yanayin Aunawa | Siffar Hanya | Abin Da Ya Nuna |

|---|---|---|

| Thermal Homogeneity | Bincika zafin jiki na narkewa a titin dunƙule | Ko da dumama |

| Material Homogeneity | Yi nazarin haɗuwar launi a samfuran narke | Ko da hadawa |

| Fihirisar Ayyuka na Screw | Ya haɗu da yanayin zafi da na kayan abu | Gabaɗaya ingancin narkewa |

Ganga mai dunƙule wanda ke haɗawa da kyau yana ba masana'antun ƙarin iko akan ingancin samfur kuma yana rage sharar gida.

Mabuɗin Bambance-bambance a cikin Zane-zanen Screw Barrel

Geometry da Girma

Screw ganga geometry yana siffanta yadda filastik ke motsawa da narkewa a cikin injin. A cikin gyare-gyaren kwalabe, ganga mai dunƙule sau da yawa yana da tsawon tsayi zuwa diamita (L/D) idan aka kwatanta da gyaran allura. Wannan karin tsawon yana ba da filastik karin lokaci don narke da haɗuwa, wanda yake da mahimmanci don yin karfi, kwalabe masu tsabta. Bottle Blow gyare-gyaren dunƙule ganga yawanci yana da fasalin tafki a hankali da tashoshi masu zurfin ciyarwa. Waɗannan zaɓukan ƙira suna taimaka wa dunƙule su riƙa riƙon robobi da ƙirƙira daidaitaccen parison.

Injection gyare-gyaren dunƙule ganga, a daya bangaren, yakan zama guntu. Suna mayar da hankali kan narkewa da sauri da kuma allurar filastik a cikin wani tsari. Gajeren tsayi yana taimakawa saurin lokacin zagayowar kuma ya dace da yanayin saurin yin gyare-gyaren allura. Geometry na kowace ganga mai dunƙulewa ya dace da bukatun tsarin sa, daidaita narkewa, gaurayawa, da matsa lamba.

Lura: Madaidaicin lissafi na iya haɓaka ingancin narkewa da rage amfani da kuzari ta hanyar sarrafa yawan juzu'i da zafin abubuwan filastik.

Rabon Matsi da Yankunan Aiki

Matsakaicin matsi shine maɓalli mai mahimmanci na ƙirar ganga mai dunƙulewa. Yana auna nawa dunƙule ya matsa robobin yayin da yake motsawa daga yankin ciyarwa zuwa yankin aunawa. A cikin gyare-gyaren kwalabe, Bottle Blow gyare-gyaren dunƙule ganga sau da yawa yana amfani da matsi mafi girma. Wannan yana taimakawa haɓaka matsi da ake buƙata don samar da santsi mai santsi mara kumfa. Matsakaicin mafi girma kuma yana haɓaka haɗuwa da narke homogeneity, wanda ke haifar da mafi kyawun tsabtar kwalba da ƙarfi.

Ganga mai dunƙulewa na allura na iya amfani da ƙaramin matsi ko matsakaici, ya danganta da kayan. Misali, ƙarancin matsawa na iya haifar da lahani kamar splay a cikin polystyrene, yayin da babban rabo yana inganta haɓakawa kuma yana rage lokacin sake zagayowar. Duk da haka, idan rabo ya yi yawa ga wasu kayan kamar ABS, zai iya haifar da rashin zaman lafiyar tsari da rashin cika narkewa. Zane-zane na yankuna masu aiki - ciyarwa, canji, da ma'auni-kuma suna taka rawa sosai. Daidaita zurfin da tsayin waɗannan yankuna yana canza yadda filastik ke narkewa da gudana, yana shafar matsa lamba da aikin dunƙulewa.

- Matsakaicin matsi dole ne ya dace da nau'in polymer da buƙatun tsari.

- Tsarin da ya dace na yankunan aiki yana tabbatar da barga mai narkewa kuma yana hana lahani.

- Kyakkyawan daidaita waɗannan fasalulluka na iya haɓaka ingancin narkewa da haɓaka ƙarfin shuka.

Bukatun Sarrafa Kaya da Filastik

Daban-daban hanyoyin gyare-gyare suna da buƙatun filastik na musamman. Dole ne ganga mai gyare-gyaren ƙwalƙwalwa dole ne ya ɗauki abubuwa da yawa, daga polyethylene mai girma (HDPE) zuwa polypropylene (PP). Yana buƙatar narke kuma ya haɗa waɗannan kayan a ko'ina don ƙirƙirar parison tare da daidaiton kauri. Wannan yana da mahimmanci saboda rashin daidaituwa na narkewa zai iya haifar da rauni mai rauni ko kwalabe mai girgije.

Ganga mai gyare-gyaren allura suna mai da hankali kan narkar da robobin da sauri da kuma yi masa allura a cikin wani tsari. Sau da yawa suna aiki tare da kayan da ke buƙatar madaidaicin sarrafa zafin jiki da saurin filastik. Wasu kayan, kamarhigh-danko resins, na iya zama ƙalubale don aiwatarwa a cikin gyare-gyaren allura. Zane mai dunƙule ganga dole ne ya lissafta waɗannan bambance-bambance don tabbatar da aiki mai sauƙi.

| Al'amari | Extrusion Blow Molding (EBM) | Injection Blow Molding (IBM) |

|---|---|---|

| Tsara | 5% zuwa 30%., yana buƙatar sake yin amfani da su, yana ƙara sauye-sauye. | Ƙananan tarkace tare da kayan aiki masu dacewa; kawai daga farawa ko canza launi. |

| Tsarin Filastik | An hura Parison a babban zafin jiki, ɗan daidaitawa. | Wasu fuskantarwa yayin allura, inganta kaddarorin. |

| Farashin kayan aiki | Ƙananan, mai kyau ga ƙananan gudu. | Mafi girma, amma inganci don manyan gudu. |

| Tsaratarwa | Layukan mutuwa mai yiwuwa ko lahani. | Share kwantena saboda ingantaccen sarrafawa. |

| Ƙarƙashin Tsoka-kashe Tabo | A halin yanzu, na iya shafar bayyanar. | Babu, mafi kyawun kamanni da ƙarfi. |

| Kasa Tura-kashe | Mai wahala saboda tsinkewa. | Mafi sauƙi tare da matosai masu ja da baya. |

Tukwici: Daidaita dadunƙule ganga zanezuwa kayan aiki da tsari yana taimakawa rage raguwa, inganta tsabta, da yin kwalabe masu karfi.

Saka Juriya da Daidaituwar Abu

Juriya na sawa babban damuwa ne ga gyare-gyaren kwalabe da gyaran allura. Surkulle da ganga suna fuskantar gogayya akai-akai da matsi daga robobin motsi. Fillers da ƙari a cikin filastik na iya yin lalacewa har ma da muni. Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwaƙwalwadunƙule gangasau da yawa yana amfani da ƙarfe mai inganci na nitrided, alloys bimetallic, ko kayan kwalliya na musamman kamar tungsten carbide don yaƙi da lalacewa da lalata. Wadannan kayan suna taimakawa dunƙule ya daɗe, koda lokacin sarrafa polymers masu lalata ko lalata.

Ganga masu gyare-gyaren allura na iya amfani da kayan kamar Nitralloy nitride, D2 Tool steel, CPM 10V, ko ma carbide don ayyuka masu wahala. Kowane abu yana ba da matakan kariya daban-daban daga lalacewa da lalata. Misali, CPM 10V yana aiki da kyau tare da robobin da aka cika gilashi ko kuma masu riƙe da wuta, yayin da ganga na carbide sun fi kyau ga kayan abrasive sosai. Daidaita dunƙule da kayan ganga yana da mahimmanci don guje wa matsaloli tare da faɗaɗa thermal da ɗaure.

- Matsalolin lalacewa na yau da kullun sun haɗa da wedging, abrasive wear, da rashin daidaituwa.

- Yin amfani da kayan da suka dace da sutura suna kara tsawon rayuwar ganga mai dunƙule.

- Binciken tsarin sawa na yau da kullun na iya taimakawa wajen gano matsaloli da wuri da jagorar haɓaka ƙira.

Tuna: Kayan da aka zaɓa da kyau yana sa injin yana gudana cikin sauƙi kuma yana rage lokacin yin gyare-gyare.

Features na Buga Buga kwalaba Screw Barrel Features

Daidaita Tsara don Ingancin Parison

Masu masana'anta suna tsara ganga mai gyare-gyaren Bottle Blow tare da fasali da yawa don haɓaka ingancin parison. Wadannan gyare-gyare suna taimakawa ƙirƙirar kwalabe tare da ko da ganuwar da filaye masu santsi. Ga wasu mahimman zaɓen ƙira:

- Gangarin dunƙule yana ba da cikakken iko kan yadda filastik ke narkewa da gudana. Wannan sarrafawa yana taimakawa kiyaye kaurin bangon parison ɗin uniform, wanda ke haifar da kwalabe masu kyau.

- Injiniyoyin suna amfani da kayan aiki masu daraja kamar nitrided karfe, bimetallic alloys, da kuma tungsten carbide coatings. Wadannan kayan suna sa ganga mai dunƙulewa ya fi ɗorewa da juriya da lalacewa, don haka yana ci gaba da aiki da kyau akan lokaci.

- Keɓancewa na kowa ne. Masu kera za su iya canza diamita na dunƙule, rabon tsayi-zuwa diamita (L/D), siffar jirgin, da rufin saman. Waɗannan zaɓuɓɓukan suna ba su damar daidaita ganga mai dunƙule zuwa robobi daban-daban da buƙatun samarwa.

- Waɗannan fasalulluka na ƙira suna taimakawa haɓaka mahimman abubuwan sarrafawa. Misali, za su iya rage lokutan sake zagayowar, inganta sanyaya, da kuma sanya girman kwalbar daidai.

Kyakkyawan tsarawaBottle Blow gyare-gyaren dunƙule gangayana ba kamfanoni ƙarin iko akan samfurin ƙarshe, yana sauƙaƙa samar da kwalabe waɗanda ke da kyau kuma suna aiki da kyau.

Kula da Zazzabi da Ma'aunan Halitta

Sarrafa yanayin zafi yana taka rawa sosai wajen gyare-gyaren busa. Dole ne ganga mai dunƙulewa ta ajiye robobin a daidai yanayin zafin da ya dace don tabbatar da cewa ya narke sosai kuma yana gudana cikin sauƙi. Idan zafin jiki ya yi girma ko ƙasa da ƙasa, filastik ba zai samar da kyakkyawan parison ba.

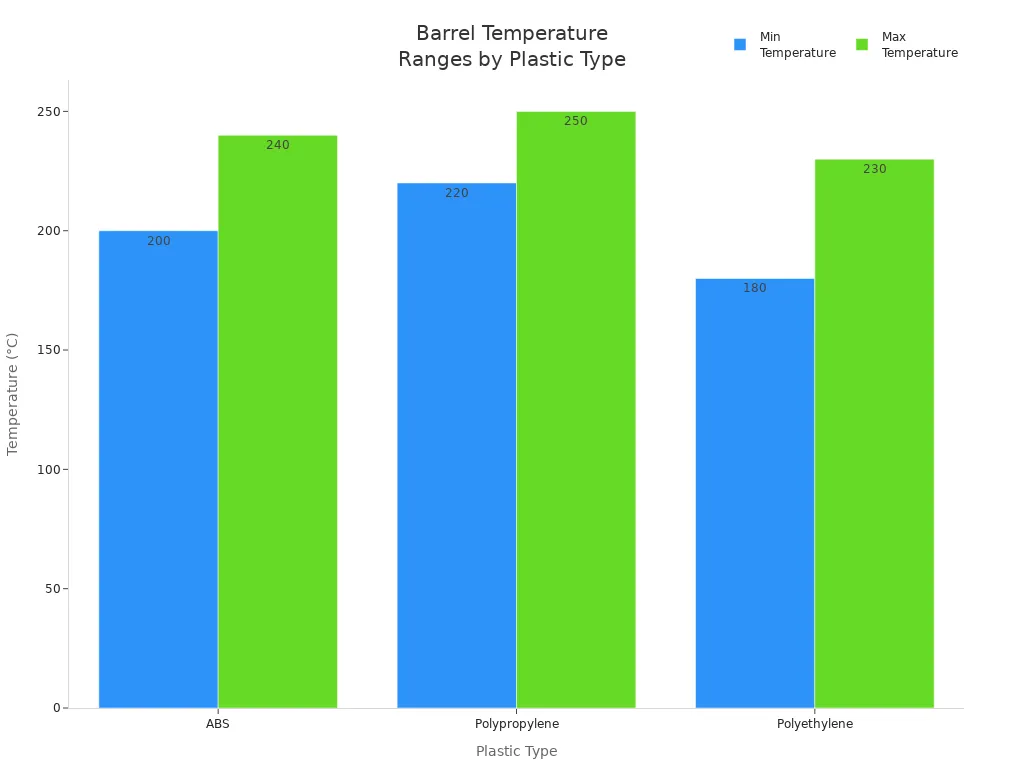

| Nau'in Filastik | Yawan Zazzabi na Ganga (°C) |

|---|---|

| ABS | 200-240 |

| Polypropylene | 220-250 |

| Polyethylene | 180-230 |

Masu aiki suna amfani da makada masu zafi da na'urori masu auna firikwensin don sarrafa waɗannan yanayin zafi. Zane-zanen dunƙule kuma yana shafar yadda filastik ke yin zafi da haɗuwa. Wuraren zafi na iya bayyana a cikin yankin canji na dunƙule, yana haifar da zafin jiki don haɓaka. Don gyara wannan, masana'antun na iya daidaita saurin dunƙulewa, ƙara magoya baya sanyaya, ko sanya makada mai zafi. Waɗannan matakan suna taimakawa ci gaba da narke zafin jiki, wanda shine maɓalli don yin kwalabe tare da daidaiton inganci.

Kyakkyawan gyare-gyaren kwalabe mai kyaudunƙule ganga zanekuma yana inganta dabi'u. Fasaloli kamar sukukulan ciyarwa da jirage masu zurfi suna taimakawa robobin narke da kyawu. Sassan haɗewar shinge kusa da ƙarshen dunƙule suna haɗa polymer daidai. Wannan narkewar uniform yana haifar da tsayayyen samuwar parison da ƙarancin lahani.

Lokacin da zafin jiki ya tsaya tsayin daka kuma narke ya zama iri ɗaya, tsarin yana tafiya da sauƙi kuma kwalabe suna fitowa da ƙarfi da haske.

Tasiri kan Tsaftar Kwalba da Ƙarfi

Zane na dunƙule ganga yana da kai tsaye tasiri a kan yadda bayyananne da kuma karfi da ƙãre kwalabe. Tsawon dunƙule mai tsayiTsawon tsayi zuwa diamita (sau da yawa tsakanin 24:1 da 30:1)yana ba filastik ƙarin lokaci don narkewa da haɗuwa. Matsakaicin matsi mafi girma, yawanci a kusa da 3.5:1, yana taimakawa ƙirƙirar narke mai santsi, mara kumfa. Waɗannan fasalulluka suna aiki tare don haɓaka kwararar filastik da ingancin parison.

Ci gaban fasahar dunƙule ganga ya sanya sauƙin samar da kwalabe marasa nauyi ba tare da rasa ƙarfi ba. Ingantattun kwararar kayan abu yana rage toshewa kuma yana ci gaba da gudana. Ingantacciyar hanyar canja wuri mai zafi yana taimakawa kula da yanayin yanayin aiki mafi kyau, wanda ke haifar da mafi kyawun narkewar kwalabe. Kayayyaki masu ɗorewa kamar ƙarfe na ƙarfe mai zafi da aka yi wa zafi yana nufin ƙarancin gyare-gyare da ƙarancin lokaci.

Masu masana'anta kuma za su iya keɓance ganga mai dunƙulewa don dacewa da buƙatun samarwa daban-daban. Wasu suna amfani da haɗe-haɗen na'urori masu auna firikwensin don saka idanu da matsa lamba da zafin jiki a ainihin lokacin. Wannan yana ba da damar yin gyare-gyare cikin sauri kuma yana taimakawa hana matsaloli kafin su shafi samfurin.

- Girgizawar ciyarwar abinci da jirage masu zurfi suna haɓaka narkewar guduro da gaurayawa, wanda ke da mahimmanci don yin kwalabe masu tsabta.

- Sassan haɗe-haɗe na shinge suna tabbatar da cewa polymer yana haɗuwa daidai, yana rage ƙwanƙwasa da rauni.

- Matsakaicin matsi mai girma yana ba da izini don sirara, bangon kwalabe masu sauƙi yayin kiyaye su da ƙarfi.

Tare da waɗannan gyare-gyaren ƙira, kamfanoni na iya yin kwalabe waɗanda ba kawai masu sauƙi ba amma kuma sun fi dacewa kuma sun fi karfi, suna biyan bukatun masana'antun marufi na yau.

Teburin Kwatanta: Kwalban Busa Molding vs. Injection Molding Screw Ganga

Takaitacciyar Siffar Side-da-Geshe

Lokacin kwatanta kwalban busa gyare-gyare daallura gyare-gyaren dunƙule ganga, bambance-bambance da yawa sun fito fili. Teburin da ke ƙasa yana ba da haske mafi mahimmancin fasali gefe da gefe:

| Siffar | Bottle Blow Molding Screw Barrel | Injection Molding Screw Barrel |

|---|---|---|

| Hanyar narkewar Filastik | Yana narkewa kuma yana fitar da robobi don samar da fassarorin fage | Yana narkewa da allura robobi a cikin abin da aka riga aka tsara |

| Girman samfur | Yana yin samfuran 2D mara kyau kamar kwalabe da kwantena | Yana samar da ɓangarorin 3D mara kyau tare da madaidaicin madaidaici |

| Abubuwan Amfani | HDPE, PP, PET | Acrylic, Polycarbonate, POM, PE |

| Tsarin Tsara & Daidaitawa | Zane mai sassauƙa, ƙananan daidaito | Babban madaidaici, ingantaccen guduro kwarara |

| Tsara Tsara | Yana haifar da walƙiya mai buƙatar datsa | Ba tare da ɓata lokaci ba, ba a buƙatar gyarawa |

| Farashin kayan aiki | Ƙananan, kayan aiki masu sassauƙa | Mafi girma, ƙasa da sassauƙa |

| Saurin samarwa | Sannu a hankali, ƙwarewar ma'aikaci mai mahimmanci | Mai sauri, manufa don babban girma |

| Nau'in Samfura | Manyan kwantena, hadaddun siffofi, iyawa | Ƙananan sassa, daidaitattun sassa tare da m haƙuri |

| Nauyi & Sarrafa kayan aiki | Ƙananan madaidaici, mai wuyar daidaita kaurin bango | Daidaitaccen nauyi da rarraba kayan abu iri ɗaya |

| Girman Kwantena | Kasa da 1 oz. har zuwa galan 55 | Mafi kyau ga 5 oz. ko ƙasa da haka, ba tattalin arziki sama da 16 oz ba. |

| Bukatun Mold | Nau'in ƙira ɗaya | Yana buƙatar allura da busa ƙura |

Tukwici:Kulawa na yau da kullun yana kiyaye nau'ikan ganga guda biyu suna gudana cikin sauƙi. Don gyaran gyare-gyaren kwalabe, masu aiki suna tsaftace dunƙule da ganga sau da yawa don hana ragowar haɓaka. Suna kuma lura da yanayin zafi da kuma sa mai sassa masu motsi. A cikin gyare-gyaren allura, ƙungiyoyi suna bincika dunƙule da ganga kowace shekara, bincika sauye-sauyen tsari, da kuma kula da mai da mahaɗar dumama. Waɗannan matakan suna taimakawa tabbatar da daidaiton ingancin samfur da tsawaita rayuwar kayan aiki.

Masu kera suna ganin bambance-bambance a sarari a cikin ƙirar dunƙule ganga don gyare-gyaren kwalabe da gyare-gyaren allura. Bottle Blow gyare-gyaren dunƙule ganga yana amfani da dogon juzu'i da madaidaicin sarrafa zafin jiki don haɓaka ingancin parison. Maɓalli masu mahimmanci kamar siffar dunƙule, zaɓin kayan abu, da saka idanu na ainihi suna taimakawa haɓaka inganci da daidaiton samfur.

- Screw geometry yana siffan narkewa da haɗawa, rage sharar gida da haɓaka inganci.

- Zaɓin kayan a hankali yana hana lalacewa da zafi fiye da kima, musamman tare da robobi masu lalata.

| Kalubale | Tasiri kan Masana'antu |

|---|---|

| Zaɓin kayan abu | Yana hana lalacewa kuma yana tsawaita rayuwa |

| Kula da yanayin zafi | Yana kiyaye tsabtar samfur da ƙarfi |

| Ayyukan aiki | Yana rage raguwa da lahani |

Zaɓin ƙirar ganga mai kyau yana haifar da mafi kyawun kwalabe, ƙarancin sharar gida, da samar da santsi.

FAQ

Menene ya bambanta ganga gyare-gyaren dunƙulewa ta daban da ganga mai gyare-gyaren allura?

Buga gyare-gyaredunƙule gangaya fi tsayi kuma yana amfani da ƙimar matsawa mafi girma. Wannan ƙira yana taimakawa ƙirƙirar parisons iri ɗaya don ƙarfi, bayyanannun kwalabe.

Ta yaya ƙirar ganga mai dunƙulewa ke shafar ingancin kwalbar?

Gangarin dunƙule yana sarrafa narkewa da haɗuwa. Kyakkyawan ƙira yana haifar da ko da kauri na bango, mafi kyawun tsabta, da kwalabe masu ƙarfi.

Shin masana'antun za su iya amfani da ganga mai dunƙule iri ɗaya don matakai biyu?

A'a, kowane tsari yana buƙatar takamaiman ganga mai dunƙulewa. Yin amfani da ƙirar da ya dace yana tabbatar da aiki mai santsi da samfurori masu inganci.

Lokacin aikawa: Yuli-25-2025